Gas and Chemical Sensors / Detectors

Multi-Gas Leak Detector works in production environments.

Press Release Summary:

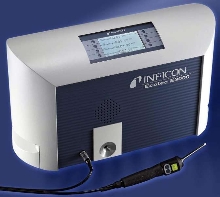

Designed to minimize operator error, Ecotec E3000 features I-Guide operator guiding-mode to ensure that correct number of locations on each unit under test is checked, and that each location is tested for predetermined minimum time. False alarms are reduced by algorithm which compensates for interfering background gases. Self-monitoring unit allows operator to verify unit is functioning properly directly at production line.

Original Press Release:

Ecotec E3000 Sets New Standard for Sniffer Leak Detection

More Reliability for Increased Productivity

Syracuse, NY - 28 April 2005: INFICON introduces Ecotec E3000, a multi-gas leak detector which brings new levels of productivity to demanding production environments. Easy to use and comfortable, Ecotec E3000 is more immune to careless sniffing operation and can minimize operator error, so the accuracy and reliability of your testing operation is improved. It can detect leaks at a greater distance from the leak location, and the sniffer tip can be moved faster without missing leaks. Ecotec E3000 dramatically reduces false alarms by ignoring background gases and has an innovative operator guiding-mode. This high-performance leak detector provides dependable leak checking and lowers your cost-of ownership for final testing of refrigerators, freezers, automotive air conditioners and similar products.

Innovative features support foolproof operation

Ecotec E3000 has been designed for maximum productivity. It can minimize operator error due to I-Guide, a unique operator-guiding mode that ensures the correct number of locations (for example, the number of joints) on each unit under test is checked, and that each location is tested for the predetermined minimum time. False alarms are reduced due to a newly developed algorithm which compensates for interfering background gases, such as foaming agents. Ecotec E3000 monitors itself and notifies the operator of any trouble before any leaks can be missed. For maximum flexibility, the unit can be operated, after initial setup, via the probe display without access to the main unit. The built-in ECO-Check reference leak allows the operator to verify the unit is functioning properly directly at the production line at any time.

For more information, contact INFICON, Two Technology Place, East Syracuse, NY 13057-9714, + 1.315.434.1100, email: reachus@inficon.com, www.inficon.com.

About INFICON

INFICON is a leading developer, manufacturer and supplier of innovative instrumentation, critical sensor technologies, and advanced process control software for the semiconductor and vacuum coating industries and other industrial applications. These analyses, measurement and control products are vital to original equipment manufacturers (OEMs) and end-users in the complex manufacturing of semiconductors, flat panel displays, magnetic and optical storage media and precision optics. INFICON also provides essential instrumentation for gas leak detection to the air conditioning/refrigeration industries, and toxic chemical analysis for emergency response and industrial hygiene. Headquartered in Syracuse, New York, INFICON has world-class manufacturing facilities in the United States and Europe and worldwide offices in the U.S., China, France, Germany, Japan, Korea, Liechtenstein, Singapore, Switzerland, Taiwan, and the United Kingdom. For more information about INFICON and its products, please visit the Company's website at www.inficon.com.