Motorized Vertical Elevator Stage provides precise positioning.

Press Release Summary:

Constructed of black-anodized aluminum alloy, AZ60-A non-cantilevered moving wedge vertical elevator stage supports up to 15.43 lb loads without loss of parallelism. Dimensions are 183.7 x 80 x 38 mm (~42 mm when raised), 60 x 95 mm drilled and tapped stage has 4 mm vertical travel, and travel speeds reach 2.5 mm/sec. Design provides smooth, straight (to <5 µm), vertical motion and parallelism (<20 µm to mounting surface). Resolutions are 1.25 µm (full step) to 0.125 µm (1/10 micro step).

Original Press Release:

High Precision Vertical Elevator Stage from OES

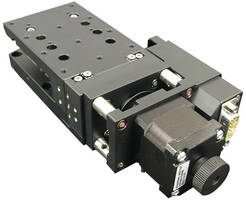

Van Nuys, CA – The AZ60-A Motorized Vertical Elevator Stage from Optimal Engineering Systems, Inc. (OES) is a low profile, compact 183.7 mm x 80 mm x 38 mm ~ 42mm (raised), (7.232in x 3.150 in. x 1.496 ~ 1.654 in.) low cost, high resolution, wedge type, vertical elevator stage for applications requiring precise vertical positioning. The 60 mm x 95 mm (2.362 in. x 3.740 in.) drilled and tapped stage has a vertical travel of 4 mm (0. 157 In.). Six crossed roller guides and a precision ground 8 mm dia. 250 µm/turn lead ball screw provides smooth, straight (straightness to <5 µm) vertical motion, and parallelism (<20 µm to the mounting surface), and high resolutions to 1.25 µm (full step), 0.625 µm (1/2 step), and 0.125 µm (1/10 micro step), and repeatability to +/- 0.5 µm. Travel speeds are up to 2.5 mm/sec. Applications for the AZ60-A elevator stage include: Photonic alignment, wafer inspection, precision vertical alignment, laser marking, optical positioning, testing, inspection, assembly, sampling, laser drilling and machining in a broad range of industrial, medical, semiconductor, and research facilities.

The AZ60 - A Elevator Stage is constructed of black-anodized aluminum alloy and weighs just 1.14 kg (2.51lbs). A powerful 35 mm NEMA 14 1.8O 2-phase stepper motor has a double ended shaft with a knob for manual adjustments. This knob may be replaced with a quadrature encoder for position verification. The non-cantilevered moving wedge elevator stage has a load capacity of 7 kg (15.43 lbs) without concern for loss of parallelism, and the base plate has easy to access holes for mounting.

About OES – Optimal Engineering Systems, Inc. (OES) is a manufacturer of motion control products including: Stepper motor controllers and drivers, solenoid electronics, and positioning stages and slides. Applications include: Animation, automated assembly systems, automation, CNC machines, flight simulation, inspection systems, linear and rotary stages, machine tools, medical devices, motion control camera boom systems, optical comparators, CMMs, pan-tilt gimbals, PCB assembly & inspection, pick-and-place, positioning stages, robotics, scanners, security cameras, telescope drive mechanisms, time-lapse photography and winders.

Some of the industries OES serves are: Aerospace, Astronomy, Chemical, Communications, Educational Institutes, University, Colleges, Government Agencies, National Labs, Manufacturing, Medical, Metrology, Military, Motion Control, Museum, News Agencies, Semiconductor and Test Equipment. Optimal Engineering Systems, Inc's. competitive advantage is its state-of-the-art in-house manufacturing facility in North America enabling OES to supply clients with custom designed orders or high volume just-in-time deliveries globally.

For additional information contact Joseph Hank at Optimal Engineering Systems, Inc. (OES), 6901 Woodley Ave, Van Nuys, CA 91406; Tel 888-777-1826, +1 818-222-9200, E-Mail sales@oesincorp.com or visit the website at http://www.oesincorp.com.