Motion & Robotics Now Even Easier Comprehensive PLCopen Certification for KEBA's KeMotion

KEBA counts on user-friendly axis integration in its solution for motion applications and demanding robotics tasks which was specially developed for this purpose. All axes can be accessed comprehensively and uniformly via online teach-in in a familiar CoDeSys environment - regardless of whether it is from the PLC motion or the robotics environment.

The requirements of PLCopen Part 2 and Part 4 have now also been fulfilled in their entirety. The PLCopen certificate for the KeMotion system was awarded officially to KEBA at the last SPS/IPC/Drives 2011 trade fair in Nürnberg.

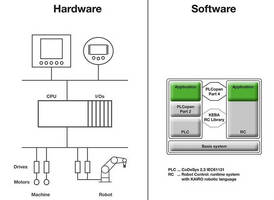

KeMotion control solution unites PLC, motion and robotics

The straightforward and quickly programmable combination of PLC, motion and robotics makes KEBA's KeMotion control system solution unique. KeMotion has been certified in accordance with PLCopen Part 2 since Version 2.40. Additionally, the robotics can also be controlled via PLCopen Part 4 from the PLC environment. This means that complex robot paths can be generated in the user-friendly online robotics teach-in environment. These are then implemented in the machine process via PLCopen Part 4 in the PLC environment.

Easy to use thanks to familiar programming environment

The user benefits from a single, familiar programming environment. All robot types plus the entire process and machine sequence are controlled simultaneously with just one program run.

The PLC has constant access to all robot data. As a result, robot functions can be manipulated easily and quickly via the PLC. This includes, for example, program management and operating mode management and the readout of online sensor data for path planning.

Thanks to the unique combination of PLC, motion and robotics, machine and robot control functions are perfectly tuned to each other through KeMotion. The robot is an integral part of the entire machine control system and a dedicated robot control system is not necessary.

The hardware and software for the complete system comes from a single manufacturer. This ensures a perfect interplay of all components and data and events are recorded in a uniform manner. The consistent, user-optimised HMI to control robotics, the process and the machine offers the best possible user-friendliness.

This results in a major potential saving as training, operation and servicing are required for only one instead of two pieces of equipment. Moreover, thanks to less cabling being required, there is also an effective reduction in manufacturing and service costs.

With the fulfilment of PLCopen Part 4 the user-friendly combination of KEBA's independent robotics runtime system and the standard CoDeSys environment is now easily possible.

Besides this KEBA has its own additional libraries for the use of further robotics features such as tracking, cooperating robots and sensor-based robot control, for example.

KeMotion Product Manager Harald Kampenhuber and PLCopen Chairman Eelco van der Wal handing over the PLCopen certificate to KEBA at the SPS/IPC/Drives 2011 trade fair in Nürnberg.

KEBA Industrial Automation

The technology expert for optimized industry solutions

KEBA AG is a globally successful high-tech company that focuses on the automation of industry, banking and service processes, plus energy automation. The high-quality hardware and software components and system solutions are developed and produced in line with the company's guiding principle of "Automation by innovation".

KEBA's industrial automation business area concentrates on the automated control of robots, injection molding machines, processes and automation solutions for mechanical engineering in general. Furthermore, the Austrian company is the market leader for mobile operating terminals in industrial applications.

A wide range of series products are available for every possible application. In addition to this, experts develop client-specific, individual automation solutions quickly which are then implemented professionally in accordance with the respective requirements.

The extensive product portfolio with its perfectly interacting hardware and software modules enables KEBA to offer customized and comprehensive solutions from a single source.

This is why so many well-known and internationally successful mechanical engineering groups, robot manufacturers and service providers place their trust in KEBA products.

For more information please contact:

Werner Hentscholek

Marketing Communications, Industrial Automation

KEBA AG

Gewerbepark Urfahr, A-4041 Linz, Austria

Tel.: +43 732 7090-22610

hnt@keba.com

www.keba.com