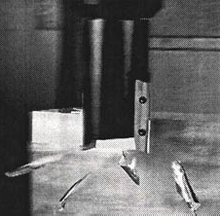

Milling Cutters offer consistent cutting edge.

Share:

Press Release Summary:

Aerostell(R) 5182 VZ pocket milling cutters with SFZ grade inserts are designed for roughing aluminum and finishing aluminum, pH stainless steel, cast iron, and high temperature alloys. They offer extended tool life due to sub-micrograin carbide, and wear resistance due to insert hardness, ground surface finish and edge preparation.

Aerostell(R) 5182 VZ pocket milling cutters with SFZ grade inserts are designed for roughing aluminum and finishing aluminum, pH stainless steel, cast iron, and high temperature alloys. They offer extended tool life due to sub-micrograin carbide, and wear resistance due to insert hardness, ground surface finish and edge preparation. Original Press Release:

New 5182 VZ Aerostell Milling Cutters Improve Productivity And Quality Between 20% And 70%

La Vergne, TN-- Stellram's Aerostell pocket milling cutters are

specifically designed for high-efficiency machining. Stellram's SFZ grade inserts are the best choice for roughing aluminum and

finishing of aluminum, PH stainless steels, cast iron, and high

temperature alloys.

Aerostell's consistent cutting edge assures longer tool life by

reducing edge build-up, which is especially intense when machining thin walled sections.

Other Aerostell advantages include:

* Extended tool life due to sub-micrograin carbide

* Reduced tool inventory of 1:3

* Exceptional wear resistance due to insert hardness, ground surface finish and edge preparation

* Greater precision and surface finish

* Maximum cutting depth = insert edge length

* Increased machine "up" time

* Lowered cutting forces

Stellram is a globally integrated technological leader in the

development of metalcutting answers for turning, milling, threading, drilling and grooving applications.

Worldwide resources in materials, research, engineering and

application expertise enable the company to be a single-source

provider for all metalcutting needs.

In addition to aircraft aluminum and titanium applications, Aerostell cutters are also used in high volume automotive machining of alloy wheels and cast iron components.