Mill-Max Introduces a Line of Solderless Press-Fit Receptacles with Hexagon Shaped Flange

Press Release Summary:

- Receptacles have an open bottom to allow leads to pass through and are designed to have a minimum overall length

- Smallest receptacles has a lead acceptance range of just .008” - .013” (,2 - ,33 mm) diameter while the largest accepts .045” - .065” (1,14 – 1,65 mm)

- Each receptacle is precision machined from brass alloy and is fitted with a highly reliable multi-finger beryllium copper contact

Original Press Release:

Mill-Max Zero Profile Press-Fit Receptacles Keep Components Flush

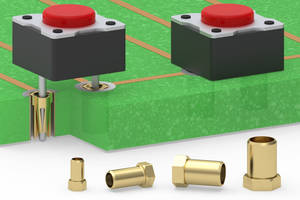

Solderless press-fit receptacles for flush mounting in PCB’s

Oyster Bay, NY, 22 January, 2019 – Mill-Max Manufacturing Corp., Inc. today announces a new line of solderless press-fit receptacles delivering flush mount solutions for achieving the lowest profile connections possible. Mill-Max now offers even more variety by adding 10 new receptacles capable of accepting a broad range of mating lead diameters to suit a variety of interconnect requirements, all while maintaining a zero above board profile.

The ongoing pursuit to reduce product and/or package size presents challenges for making connections between PCB’s and devices. With the zero profile receptacles, Mill-Max has eliminated any above-board connector protrusion, enabling overall package height to be reduced. These receptacles have a precision machined, hexagon shaped flange which is pressed into the PCB plated through hole until flush with the surface of the board. No soldering is required as the press-fit forms a gas-tight connection with a properly specified plated through hole. After installation, the zero profile PCB contacts enable a broad range of devices to be plugged in while minimizing overall interconnect height. They may be used on both traditional and rigid backed flex PCB’s.

The smallest of the receptacles has a lead acceptance range of just .008” - .013” (,2 - ,33 mm) diameter while the largest accepts .045” - .065” (1,14 – 1,65 mm). All the receptacles have an open bottom to allow leads to pass through and are designed to have a minimal overall length; useful features for low profile board stacking applications. The open bottom eliminates the need for precise lead trimming.

Each receptacle is precision machined from brass alloy and is fitted with a highly reliable multifinger beryllium copper contact. The standard plating for these receptacles is 10 u” gold on the shell and 30 u” gold on the contact to ensure the highest conductivity, corrosion resistance and durability. The gold plating on the shell also eliminates any issues with material skiving leading to bridging during press-fit into the PCB.

For more information, please visit http://www.mill-max.com/PR690.

About Mill-Max

Mill-Max is the leading US manufacturer of machined interconnect components with a vertically integrated manufacturing facility headquartered at 190 Pine Hollow Rd., Oyster Bay, NY 11771. Its full product line includes spring-loaded connectors, SIP, DIP, PGA and BGA sockets, board-to-board interconnects and pin headers, surface mount and custom products, PCB pins and receptacles, solder terminals, wrapost receptacles and terminals. The company’s complete manufacturing facility includes engineering, tooling, primary and secondary machining, stamping, plating, injection molding, and assembly.