Microperforation Systems provide adjustable hole sizes.

Press Release Summary:

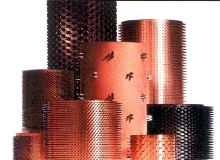

VentPerf needling tools and systems are suited for micro-perforation and cutting of film, paper, foil, laminates, and non-wovens. Various designs provide ventilation, moisture release, or product expansion for agricultural and consumer good packaging as well as technical materials. Up to 600 holes/sq in. are attainable at speeds to 600 fpm. Products can be integrated into in-line processes, or equipped with unwind and rewind for stand-alone operations.

Original Press Release:

Introducing VentPerf Microperforation Systems for Film, Paper, Laminates, and Foil

Cincinnati, OH - New VentPerf needling tools and systems from Schober USA are ideal for micro-perforation and cutting of film, paper, foil, laminates, nonwovens and more. Various designs are available to provide ventilation, moisture release or enhanced product expansion for agricultural and consumer good packaging as well as technical materials. They are ideal for produce packaging, plastic "floating row covers", wallpaper, and nonwoven products including hospital gowns, smocks, lab coats, and more. Up to 600 holes per square inch are attainable at speeds to 600 feet/minute - with no special operator skills required. Hole sizes are adjustable. Tools for virtually any pattern can be supplied.

The VentPerf product line can be easily integrated into in-line processes, or equipped with optional unwind and rewind for stand-alone operations. Motor-driven VentPerf-Holt includes temperature controls and digital readouts for hot needling of foam and film-like web materials. VentPerf-Cold can be web- or motor-driven, and is ideal for cold needling of paper and film-like web materials. VentCut, a version of the VentPerf-Cold line, is ideal for agricultural and packaging products that require enhanced airflow and structural expansion. Custom designs and special tools are available for materials like foam, aluminum and more.

Schober USA is the North American subsidiary of Schober GmbH - a worldwide leader in rotary web converting technologies for the Label-, Packaging-, Personal Care, and general Paper, Film and Foil converting industries. They customize technologies to suit particular customer requirements, often combining rotary technologies and custom developing processes to do so. For more information, contact David Grove at Schober USA, 11237 Grooms Road, Cincinnati, OH 45242, (513) 489 - 7393, or via e-mail at solutions@schoberusa.com. Their extensive product line and capabilities can be viewed online at www.schoberusa.com.