Metrology System speeds electronic assembly.

Press Release Summary:

Equipped with digital megapixel cameras, 450 x 450 mm stage, and CAD-driven Elements software, non-contact Benchmark 450 provides electronic assembly process verification. BLAZE(TM) continuous image capture feature captures multiple images as part continually moves beneath system optics. Using library of pre-configured component routines to automatically create measurement programs from CAD files, Elements software enables part changeovers to be set up in minutes.

Original Press Release:

Benchmark 450 Metrology System Adds Accuracy, Speed to Electronic Assembly

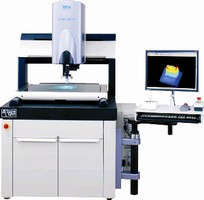

Simi Valley, CA, August 2006 - VIEW Engineering, Inc., a market leader in high-precision metrology systems, announces the VIEW Benchmark 450 non-contact metrology system for high throughput, electronic assembly process qualification. Equipped with the latest digital megapixel cameras, continuous image capture, and VIEW's unique CAD-driven Elements software, the Benchmark 450 provides high productivity and precision in the lab or on the production floor.

VIEW will showcase this powerful configuration in booth D-4618 at IMTS in Chicago - September 6-13th, 2006.

Digital megapixel cameras extend the imaging power of the Benchmark 450's unique dual camera optical system. The larger pixel arrays of digital cameras afford a larger field of view, while the greater pixel density provides vastly improved resolution than standard cameras. This combination enables substantially faster throughput, as many more measurements can be made at each stage position.

BLAZE(TM), a continuous image capture feature, improves throughput by capturing multiple images as the part continually moves beneath the system optics. This technique maps a large surface area, joining together individual images so they can be analyzed as a whole. Depending on the part geometry, cycle time is significantly reduced without compromising measurement performance.

The addition of VIEW's unique Elements software optimizes the Benchmark 450's capabilities for SMT process metrology. With Elements, no programming is required - simply import the CAD file and you're ready to measure. Using VIEW's library of pre-configured component routines to automatically create measurement programs from CAD files, Elements enables part changeovers to be set up in minutes, not hours.

The Benchmark 450 combines mid-range travel and high accuracy in a metrology system that is equally at home in the QA lab performing first article inspection or on the production floor providing precision measurements for process control. Its 450 x 450 mm stage is suitable for large footprint parts or nested groups of smaller parts. A fixed bridge design separates the X and Y axis motions, allowing each to operate without any influence on the other. The bridge-type design also makes loading and un-loading of parts more efficient, and helps to minimize the system's overall footprint.

Advanced optics, illumination, and image processing make the Benchmark 450 a world-class metrology system. Its state-of-the-art dual-magnification optical system uses two cameras for near instantaneous magnification changes. Multi-color LED illumination systems allow use of monochromatic red, green, blue, or white light for high-resolution imaging of the toughest applications. During programming and automatic measurements, the light source and intensity for each measurement can be programmed to best illuminate the feature of interest.

ABOUT VIEW

VIEW Engineering, Inc., a Quality Vision International company, offers video and laser-based dimensional measurement systems for electronic assembly, data storage, semiconductor, telecommunications, fine machining, medical, and aerospace applications. VIEW is an industry leader in machine vision technology, lighting, optics, edge detection, and flaw detection, self-programming metrology software, and motion control.

Company Contact

VIEW Engineering, Inc.

1650 N Voyager Avenue

Simi Valley, CA 93063

805-578-5000

877-767-VIEW (8439) (toll-free)

Info1@vieweng.com

www.viewengineering.com