Material Handling System suits parts finishing operations.

Press Release Summary:

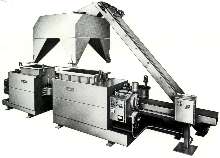

Suited for use in metal deburring and finishing applications, Model 142 includes rotary, 4-compartment hopper that drops finishing media into as many as 4 round-bowl or tub-type machines. Oscillator/screener separates finished parts from media, which returns by conveyor to hopper for reuse or storage. Features include compact size, ease of serviceability, and minimal required maintenance.

Original Press Release:

Almco Material Handling System Achieves Reduced Labor in Parts Finishing Operations

ALBERT LEA. Minnesota (August 5, 2004) - A material handling system that greatly enhances productivity in metal deburring and finishing operations is now available from equipment manufacturer ALMCO, Inc.

The Model 142 includes a rotary four-compartment hopper that drops finishing media into as many as four round-bowl or tub-type machines below. An oscillator/screener separates finished parts from the media, which then returns by conveyor to the hopper for immediate reuse or storage.

Key features of this and other ALMCO material handling systems - both standard and custom-designed - include highest quality, compact size and easy serviceability. ALMCO's engineering expertise assures maximum reliability and long life with little maintenance required.

For further information on the Model 142, contact ALMCO, Inc., 507 West Front Street, Albert Lea, Minnesota 56007, phone 1-800-521-2740, or visit the company on the Internet at www.almcoinc.com. ALMCO is a leading manufacturer and international marketer of finishing, parts cleaning and liquid filtration equipment and complete systems, which are sold through a network of independent distributors, sales representatives and ALMCO region managers.