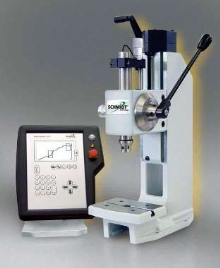

Manual Press features electronic stroke and process control.

Press Release Summary:

Intended for intricate press-fit assemblies, rack-and- pinion ManualPress 307/3000 System offers press forces from 25-900 lb, 100% process verification, force and distance monitoring, and statistical process control. It includes touch-screen display and menu-driven software. Bench-top unit features .0004 in. resolution micrometer stroke adjustment and overall adjustable stroke from 0-1.9685 in. Overall working height is adjustable from 3.543-10.236 in.

Original Press Release:

SCHMIDT Technology Introduces Manual Press with Electronic Stroke & Process Control

Cranberry Twp., PA, March 25, 2005 - SCHMIDT Technology Corporation recently introduced its precision ManualPress 307/3000 System with integrated process and electronic stroke control. Designed for intricate press-fit assemblies, for use as a stand-alone assembly station or for integration into lead manufacturing cells, this cost-effective System offers press forces ranging from 25 - 900 lbs, 100% process verification, complete force and distance monitoring, and SPC. Offering the same sophisticated monitoring normally associated with Servo Presses, the hand-operated, patented SCHMIDT® Manual Rack & Pinion Press, Model No. 307/3000 System eliminates the need for costly safety devices and guarding associated or required with powered press systems.

The precision Rack & Pinion press features a patented programmable electronic stroke control with integrated stroke lock. Preset user criteria such as the press ram reaching the mechanical stroke limit, a nominal selected press force, or a programmed stroke limit must be met before the press ram is free to return to TDC (home position). If sensors located in the press head unit uncover a problem, the System activates an electromechanical break to automatically lock the ram stroke. Corrective action can be taken immediately before additional time and materials are expended on bad parts. The System can also utilize externally installed and/or custom tooling integrated sensor devices to verify that all parts to be assembled are in place and correctly positioned before initiating the press cycle (Poke-Yoke). The ManualPress 307/3000 System compensates for different press operators and how they physically move the press handle and for the inherent yield factors of custom designed and built tooling and mounting frames that occur during the pressing cycle.

The SCHMIDT® ManualPress 307/3000 System features a touch-screen display and menu-driven software. Optional data transfer software connects the System to a Windows-based PC. Optional, comprehensive SPC software is available for process documentation establishing real time Cp & Cpk values both numerically and via graphic illustrations. Process documentation and SPC operate in the background and can be evaluated and controlled from a central location.

The No. 307 Bench-Top Press Unit features a .0004 inch resolution micrometer stroke adjustment and an overall adjustable stroke from 0 to 1.9685 inch. It is designed to accept larger tooling and assemblies, and the overall working height is adjustable from 3.543 to 10.236 inch. For tall parts or horizontal pressing needs, the press head unit and control can be ordered alone.

For additional information, call 1-800-959-1218 or visit www.schmidtpresses.com.