Machine facilitates finishing/deburring of metal parts.

Press Release Summary:

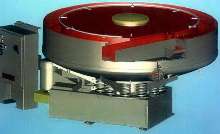

Automated Model XLR-22 features long-radius channel that measures 22 ft x 8½ in. and provides constant media mass depth and media action. Parts are automatically separated from finishing media following once-around-and-out processing or batch cycling. Offering time cycles from 4-8 min, as well as variable amplitude and vibrations per minute, compact machine has 8¼ in. tub cross-section and 8 ft dia bowl lined with 1 in. cast-molded urethane.

Original Press Release:

Innovative Long-Radius Machine from Almco Offers Multiple Benefits in Parts Finishing

ALBERT LEA, Minnesota (January 10, 2005) - A new technology in metal parts deburring and finishing has been introduced by ALMCO, Inc., in an automated, compact, round-bowl machine whose benefits to users include maximum precision, labor savings and energy cost containment.

The Model XLR-22 features a long-radius channel that is 22 feet in length and 8-1/2 inches wide. The channel provides constant media mass depth and media action to assure desired results according to the user's specific requirements.

ALMCO's long-radius technology allows parts to remain submerged in the media for a longer period, which means less likelihood that an individual part needs to be sent through the system a second time. The new technology is especially desirable in work-cell applications where equipment reliability and close coordination of all operations are important.

The highly efficient XLR-22 offers a choice of time cycles, from 4 to 8 minutes, and variable amplitude and vibrations per minute for process flexibility. Parts are automatically separated from the finishing media following once-around-and-out (OAAO) processing or batch cycling when longer deburring is required.

Bowl of the ALMCO model, which is 8 feet in diameter, is lined with 1-inch cast-molded urethane for protection of parts. It has an 8-1/4-inch tub cross-section, a full-length tub contour baffle, and automatic lubrication for the vibratory bearings.

Parts can be automatically loaded into the XLR-22 at specific metered intervals, freeing up workers for other jobs that need to be handled. The parts can be brought to the machine via conveyor for automatic loading, and removed by conveyor after automatic parts separation from the finishing media.

For further information about the innovative finishing machine, contact ALMCO, Inc., 507 West Front Street, Albert Lea, Minnesota 56007, phone 1-800-527-2740, or visit the company on the Internet at www.almcoinc.com. The 60-year-old firm is a leading manufacturer and international marketer of metal deburring, finishing, parts cleaning, and liquid filtration equipment and systems that are sold through a network of independent distributors, sales representatives and ALMCO region managers.