Linear Bearing System minimizes mounting time.

Press Release Summary:

Providing up to 0.004 in. linear precision, Compact Rail absorbs rotational positioning errors, misalignments between lateral planes, longitudinal parallelism errors, or combination of all of these while still maintaining system's original preload setting. Raceways are located on inside to protect them from damage and contaminants. Equipped with built-in, spring-loaded wipers in heads and lateral seals, sliders can carry up to 3,300 lb and can move up to 9 m/s.

Original Press Release:

Compact Rail Precision Linear Bearing Reduces Mounting Time for Engineers

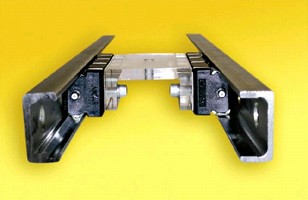

Sparta, NJ - May 14, 2008 - The Compact Rail from ROLLON Corporation has been developed to provide design engineers with a high load, intermediate-precision linear bearing system that minimizes the mounting time often spent ensuring parallel rail alignment. Providing up to 0.004-inch linear precision, Compact Rail is best suited to applications where the ease of mounting is as important as the quality of movement.

ROLLON's Compact Rail system absorbs rotational positioning errors, misalignments between lateral planes, longitudinal parallelism errors, or a combination of all of these while still maintaining the system's original preload setting. It is designed to provide smooth movement whether mounting plane parallelism can be guaranteed or not.

In addition, ROLLON has placed the raceways on the inside of the Compact Rail products to protect them from damage and contaminants while enabling the rail and slider to be mounted into small, compact, areas. Built-in, spring-loaded wipers in the heads and the lateral seals on the sides of the slider ensure they are suitable for the dirtiest of environments. These 'Lubed for Life' wipers continually deposit a thin film of oil on the races. Individual sliders can carry up to 3300 lbs. and can move up to 9 m/s.

Andrew Cook, General Manager of ROLLON Corporation, reports, "In applications where a machine tool or any other product needs great precision and rigidity, spending time guaranteeing the alignment and parallelism of the linear ways is an absolute necessity. When the product being designed does not require extreme amounts of precision and rigidity, machining the mounting surfaces and spending hours guaranteeing parallelism does not add functionality to the final product. It does, however, complicate assembly and add cost."

"Many industries like assembly, material handling, medical machinery, and packaging machinery require linear bearings that mount easily and quickly to surfaces that are not necessarily parallel. They need linear bearings that work well in contaminated environments without bellows and other extra components. ROLLON's Compact Rail is best suited to these types of applications."

For further information on the Compact Rail family of linear bearings please visit: www.rolloncorp.com or call T: 1-877 976 5566