Linear Actuators offer friction-free movement.

Press Release Summary:

Integrating linear bearing and drive mechanism in enclosed aluminum box, DL Series comes in travel lengths of 25, 50, 75, and 100 mm. Actuators feature anti-friction slide, Teflon®-coated lead screw drive, and recirculating slide guide bearings. Anti-backlash lead screw nut is spring-loaded to ensure positive movement when changing direction. Delivering 10 million inches of travel at full load, units offer straight-line accuracy of less than 2 microns.

Original Press Release:

Del-Tron DL Series Linear Actuators Offer Compact Design and Simple Assembly

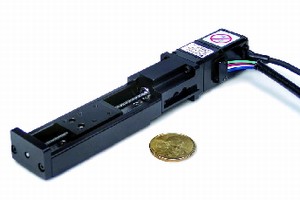

New Del-Tron DL series linear actuators offer the benefits of a space-saving design, fast and simple assembly, long life, and a competitive price. The rigid enclosed aluminum box structure provides a compact envelope that incorporates the linear bearing and drive mechanism. Integrating all components into a single unit that includes the motor mount saves assembly time and eliminates the need to source additional parts. Del-Tron's DL linear actuators are competitively priced and will outlast unsupported and unenclosed bearing drive assemblies.

Del-Tron's integrated design offers low friction and high accuracy in a compact, lightweight package. DL series linear actuators are offered in four travel lengths including 25, 50, 75, and 100 millimeters. They feature an integrated anti-friction slide and Teflon coated lead screw drive and recirculating, slide guide bearings for friction-free movement with a coefficient of friction of only 0.01.

The anti-backlash lead screw nut is spring-loaded to ensure positive movement when changing direction. The units offer straight-line accuracy of less than 2 microns and repeatability of less than 1 micron. They deliver 10 million inches of travel at their full load rating.

Options for Del-Tron DL series linear actuators include either an Oriental PK2553 stepper motor or a Sigma Mini 10 servomotor. Load capacities range up to 100 newtons with the stepper motor and 150 newtons with the servomotor. Mounts are available for other styles of motors. Photoelectric or proximity position sensors are available. An anti-dust containment cover protects moving components while also preventing particulate emissions.

Del-Tron can provide special leads, diameters, couplings, motor mounts, and vary the size, type and travel of slides on request. Del-Tron's website offers access to 2D and 3D CAD drawings which may be downloaded into the user's CAD system in a number of native CAD formats. Life and moment load calculators are also available to determine the suitability of a particular linear bearing for the intended application.

Del-Tron Precision began operations in 1974 supplying original equipment manufacturers with the world's first commercially available subminiature ball slide. Since then, thousands of Del-Tron ball slides have been incorporated into medical analyzing and testing machines, semiconductor processing equipment, computer peripherals, assembly systems, scientific instruments and many other machines. Del-Tron's modern corporate campus boasts highly automated computer controlled equipment and final inspection of 100% of all products has been Del-Tron's policy since its inception.

For more information, contact Del-Tron by phone at 800-245-5013, by fax at 203-778-2721, by email at deltron@deltron.comor on the web at www.deltron.com for a free 88 page technical product guide detailing available sizes, specification and prices. All Del-Tron Precision products may be ordered online with purchase order or credit card.