LED-Curable Adhesive facilitates catheter assembly, inspection.

Press Release Summary:

Used for bonding and assembly of catheter designs featuring Nylon 12 and PEBA, MD® 215-CTH-UR-SC provides secure bonds with facilitated cure confirmation and post-cure, bond-line inspection. Adhesive is blue to facilitate verification of placement in uncured state, and color transitions to colorless upon UV cure. Cured adhesive fluoresces bright red under low-intensity black light (365 nm). Uses include bonding lumen to balloon or hub, marker band assembly, and manifold bond joints.

Original Press Release:

Speed Assembly Processes and Ensure Complete Cures with New Catheter Adhesive

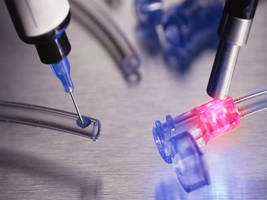

Torrington, Connecticut – Dymax Corporation has introduced MD® 215-CTH-UR-SC, an LED-curable adhesive designed for bonding and assembly of next-generation catheter designs using Nylon 12 and PEBA. Formulated with new Encompass™ technology that combines Dymax exclusive See-Cure color change and Ultra-Red™ fluorescing technologies with LED-curing capabilities, 215-CTH-UR-SC provides secure bonds with the added benefits of easy cure confirmation and post-cure bond-line inspection. The adhesive is ideal for a number of catheter applications including bonding the lumen to the balloon or hub, marker band assembly, and manifold bond joints.

While in an uncured state, this adhesive is blue in color for easy verification of placement. As the product cures with sufficient exposure to UV light, its blue color transitions to colorless and provides obvious visual confirmation that the adhesive is fully cured and the bond site secure.

215-CTH-UR-SC fluoresces bright red under low-intensity black light (365 nm), contrasting extremely well on plastics that naturally fluoresce blue in color (like PVC). This allows manufacturers to incorporate automated or manual quality inspection to verify complete and accurate placement of the adhesive after cure.

In addition to adhesives and coatings, Dymax also offers high-performance oligomers as well as a variety of dispensing and light-curing equipment. The company’s products are perfectly matched to work seamlessly with each other, providing design engineers with tools to dramatically improve manufacturing efficiency and reduce costs.

For additional information, visit www.dymax.com or contact Dymax Application Engineering at info@dymax.com or 860-482-1010. Dymax Corporation develops innovative oligomer, adhesive, coating, dispensing, and light-curing systems for applications in a wide range of markets. Major markets include aerospace, appliance, automotive, electronics, industrial, medical device, and metal finishing.