Latest PartMaker Technology to Be Shown at Eastec 2009

Share:

February 6, 2009

Most recent PartMaker release to be demonstrated at Eastec in West Springfield, MA

Fort Washington, PA - PartMaker Inc. will demonstrate the most recent version PartMaker® CAD/CAM software for CNC Mills, Lathes, WireEDM, Turn-Mill Centers and Swiss-type lathes at Eastec 2009 in West Springfield, MA. The improvements in PartMaker technology from Eastec 2008 to 2009 represent the single the largest leap in PartMaker technology in one year since the launch of PartMaker in 1994. PartMaker will be demonstrated along side other products from its parent company, Delcam, in what will be the largest CADCAM booth at Eastec. Eastec 2009 marks the first time PartMaker will be exhibited at Eastec in Delcam's booth.

"New England is one the most, if not the most, sophisticated markets in the world for manufacturing technology," says Delcam's PartMaker Inc. division President Hanan Fishman. "As a result, the latest PartMaker technology will have unique appeal to visitors to Eastec. Specifically, visitors to the Delcam booth will be very impressed to see the software's improved capability for programming on solid models, sleeker user interface and improved facility for creating set-up documentation automatically."

Seamless Solids Programming

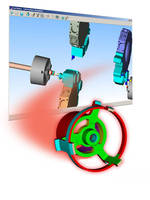

The latest version of PartMaker gives users the ability to carry out programming directly on a solid model. In PartMaker, a solid model can now be directly integrated into the programming window and tool paths can be assigned directly to the solid model. Critical manufacturing data is automatically retrieved from a solid model using the software's new "Extract Parameters from Solids" feature, thus saving time and reducing the chance for error by eliminating redundant data entry. The most commonly used solids manipulation functions are displayed via an easy to follow Solids Toolbar.

Sleeker User Interface

The latest major release of PartMaker features a sleek, new look user interface featuring, among other improvements, easy to use, user-configurable toolbars. Existing icons have been recast to make them even easier to understand. The new tool bars, populated by attractive and easy to understand icons, make the software faster and more productive for both new and existing users. With the improvements in the user interface, most functions in the software can be accessed with the click of the mouse. The revamped user interface has been carefully planned out so that existing PartMaker users will be able to use the latest version of PartMaker without any additional learning curve from previous versions.

Automatic Set-up Sheet Creation

The latest version of PartMaker allows the user to automatically generate very professional setup sheets to improve shop floor documentation. This new feature, available to those users who have licensed the PartMaker Documentation Wizard (PDW), can greatly speed up machine setup time by eliminating the sometimes tedious and time consuming process of creating setup sheets manually and by providing machine operators and set-up personnel very clear instructions about how to set-up a new job. Setup sheets are created in HTML format and can thus be viewed on any computer with an internet browser like Internet Explorer or Mozilla Firefox. The format of the set-up sheets generated by PartMaker is fully customizable by the user.

Many PartMaker users report being able to reduce machine set-up time by up to 50% versus their previous means of programming by generating accurate CNC programs and visualizing the machining process off-line. By providing even better set-up documentation than before, PartMaker users will be able to make even further strides in set-up reduction by providing machine set-up personnel with very clear instructions on how to set-up the machine to produce a particular part.

More on PartMaker

PartMaker is a Knowledge Based Machining system, allowing it to provide a substantial gain in programming efficiency by remembering the tools, material and process information necessary to machine individual part features. It thus relieves the user from reentering the same features information for subsequent parts. It also improves productivity by placing the emphasis on tool management functions.

PartMaker pioneered the field of CAM software for Turn-Mills and Swiss-type lathes with its patented Visual Programming Approach for programming multi-axis lathes with live tooling. It assures quicker learning and easier use. It makes an extensive use of pictures to help the user describe tools, part features and machining data. Synchronization of tools working on multiple spindles is achieved by a few mouse clicks.

PartMaker Inc. is a subsidiary of Delcam Plc, the world's leading developer and supplier of complete CAD/CAM software solutions. Delcam Plc is publicly traded on the AIM exchange in London. While PartMaker is sold direct in North America by PartMaker Inc. PartMaker is sold overseas through a network of sales partner offices operating in over 120 countries.

Press Contact:

PartMaker Inc. - Hanan Fishman, President

Phone/Fax: (215) 643-5077 ext. 204/(215) 653-0105

Included pictures: eastec_partmaker.jpg