Latest CAD/CAM Software Supports Fillets with Variable Radius

Press Release Summary:

- Features interactive edit toolpath capability that enables toolpath editing after initial toolpath generation

- Offers simulation center for generic NC data in turning and milling operations

- Streamlines access to Product Manufacturing Information (PMI) and metadata

Original Press Release:

OPEN MIND Introduces hyperMILL® 2021.1 CAD/CAM Software Suite

Innovations and Enhancements Optimize Machining Tools and Molds, Challenging Parts and More

NEEDHAM, MA U.S.A. (January 18, 2021) – OPEN MIND Technologies AG, a leading developer of CAD/CAM software solutions worldwide, has introduced its latest hyperMILL® 2021.1 CAD/CAM software suite which offers users new and enhanced features for efficient 3D, 5-axis and mill/turn machining. Key innovations include a new “Interactive Edit Toolpath” capability which enables toolpath editing after initial toolpath generation. Especially productive for optimizing tool and mold making, the new toolpath editing feature is easy-to-use, and offers programmers the flexibility to adapt toolpaths by trimming and removing sequences accordingly for component conditions.

To streamline access to Product Manufacturing Information (PMI) and metadata, hyperMILL® 2021.1 offers a new import function that retrieves face quality information and metadata when importing CAD data from neutral or native formats, and attaches data to the imported faces in hyperCAD®-S, making the information available to hyperMILL® and its machining processes.

"We are dedicated to maximizing and simplifying the user experience with hyperMILL® by adding innovative and enhanced features and strategies," said Mr. Alan Levine, Managing Director of OPEN MIND Technologies USA, Inc. "Keeping pace with evolving CAD/CAM programming requirements, and laying the foundation for future needs are both vital. In one example, the new PMI and Metadata Import feature in hyperMILL® 2021.1 supports future-oriented data formats that will eventually eliminate the need for blueprints."

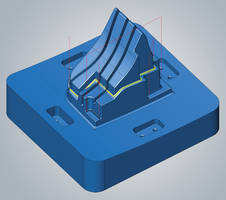

A new 5-axis Radial Machining strategy allows bottle shapes and similar cavities to be easily and efficiently programmed in hyperMILL®, resulting in high quality surface finishes. Using a new radial projection method, toolpaths are calculated quickly so that the most productive machining strategies can be applied. For optimal high precision machining, hyperMILL® “High Precision Surface Mode” and “Smooth Overlap” strategies can also be applied when using 5-axis Radial Machining, ensuring the best surface quality and clean transitions.

For high quality surface finishes and to simplify programming when flank and point milling blades, hyperMILL® 2021.1 offers several enhanced Multi-Blade strategies. No longer do blade surfaces need to be ruled for accurate programming results. Using the enhanced strategies, any number of surfaces are permitted for the suction and pressure sides, making it exceptionally easy to extend blade surfaces. Fillets with a variable radius are supported in the latest version of hyperMILL®. Also, for high accuracy, the enhanced Multi-Blade flank milling strategies result in smaller deviations on the suction and pressure side, and offer improved tool guidance along the upper boundary in the edge area.

hyperMILL® 2021.1 provides a new, powerful SIMULATION Center for generic NC data in turning and milling operations. Modeled after the hyperMILL® VIRTUAL Machining Center, the new, modern SIMULATION Center is integrated in hyperMILL®, and offers an intuitive operating environment for faster simulation, independent collision checking and extensive analysis functions.

Additional new features in hyperMILL® 2021.1 include a new, easy-to-use “XY Optimization” command for optimal 3D profile finishing. In the hyperMILL® Mill-Turn Module, the high-performance mode has been integrated into a 3-axis simultaneous roughing strategy, combining the advantages of HPC and simultaneous turning. For the simplified alignment of components, hyperCAD®-S has a new “Align Best Fit” machining command that allows like-geometry components to be aligned with one another using defined pairs of points.

Click Here to Read More Details on hyperMILL® 2021.1

About OPEN MIND Technologies AG

Headquartered in Wessling, Germany, OPEN MIND is one of the world's leading developers of powerful CAM solutions for machine and controller-independent programming. The company develops optimized CAM solutions that include many innovative features unavailable elsewhere, to deliver significantly higher performance in both programming and machining. Strategies such as 2.5D, 3D, as well as 5-axis milling, mill/ turning, and machining operations like HSC and HPC, are efficiently designed into the hyperMILL® CAM system, providing maximum user benefit and compatibility with all current CAD solutions and extensive programming automation. OPEN MIND strives to be the best, most innovative CAD/ CAM developer in the world, and has earned the top five ranking in the CAD/ CAM industry according to the 2020 NC Market Analysis Report by CIMdata. OPEN MIND CAD/ CAM solutions meet and exceed the requirements of the most demanding industries such as automotive, tool and mold manufacturing, production machining, medical, job shops, energy and aerospace industries, and is represented in all key markets of Asia, Europe and the Americas. OPEN MIND is a Mensch und Maschine Company. http://www.mum.de/ For more information visit https://www.openmind-tech.com/en.html.

Editorial Contact:

Michael McCue

McCue & Associates LLC

978-733-1353

mmccue@mccueassociates.com

OPEN MIND Contact:

Alan Levine

OPEN MIND Technologies USA, Inc.

339-225-4557

alan.levine@openmind-tech.com