Kitting Software manages manual and automated systems.

Share:

Press Release Summary:

FastPic4 inventory management and control software uses a printed pick list that requires one kit number. It directs picking mechanisms automatically to all components that make up said kit. Designed to manage manual and automated storage and retrieval systems, it can manage multiple work zones and equipment. FastPic4's kitting interface includes grid field, customizable text and bar code scanning.

FastPic4 inventory management and control software uses a printed pick list that requires one kit number. It directs picking mechanisms automatically to all components that make up said kit. Designed to manage manual and automated storage and retrieval systems, it can manage multiple work zones and equipment. FastPic4's kitting interface includes grid field, customizable text and bar code scanning. Original Press Release:

Parts Kitting Offers Improved Operating Efficiencies

A parts kitting strategy can help companies increase operating efficiencies through more effective management of component parts.

Kitting is the storage and retrieval of multiple stock-keeping units (SKUs) to create a new part in assembly operations. Kitting improves productivity by reducing stock picking time and increasing picking accuracy. The methodology is used in a variety of industrial product manufacturing, assembly and service operations where several components must be combined to create a finished part or sub-assembly.

Almost any size organization can benefit from re-evaluating its logistics methodologies in terms of kitting, according to Doug Card, Director, FastPic Systems, developer of advanced inventory management and control software.

Almost any size organization can benefit from re-evaluating its logistics methodologies in terms of kitting, according to Doug Card, Director, FastPic Systems, developer of advanced inventory management and control software.

"Kitting can have an immediate positive effect on worker productivity by not only reducing the amount of time it takes to pick parts from storage, but also on the shop floor where workers are assured of having the right parts at hand for a specific task," Card said.

When the correct parts, and the correct quantity of each part, necessary for an operation are identified and retrieved, the employee productivity increases dramatically.

"If incorrect parts reach the production or assembly floor, the process itself must be halted until the correct parts are retrieved, seriously reducing productivity and employee morale," Card said. "When workers have the correct parts for an operation, product and process quality improve and remain consistently good from finished piece to finished piece and worker productivity improves as well."

Plus, a kitting strategy can reduce inventory by using component parts as needed rather than creating sets of parts in advance that remain on shelves waiting for use on the shop floor, according to Card.

From Simple Lists to Advanced Storage and Retrieval

Kitting can be as simple as preparing a hand written list that includes the contents of each kit and an identifier that indicates to which process the kit belongs. This basic approach is effective even in shelving and rack type storage systems.

Inventory management and control software, such as FastPic Systems' FastPic4, can improve throughput and productivity using a printed pick list. Operators need only the one kit number and the software directs them automatically to all of the components that make up that kit. "This virtually eliminates mis-picks," Card said.

FastPic4 software is designed to manage virtually all manual and automated storage and retrieval systems including shelving and rack, pick-to-light, horizontal carousels, and vertical storage devices. Its ability to manage multiple work zones and equipment also provides a foundation for those companies that wish to upgrade manual systems up to fully automated storage and retrieval operations in the future.

Automated storage and retrieval systems such as carousels, vertical lift modules (VLMs) and pick-to-light systems from leading suppliers such as Remstar International, Westbrook, ME, can be used with printed pick lists to add a level of inventory security and improved system throughput. Carousels and VLMs deliver stored items to the operator at an ergonomically correct height, eliminating costly travel time searching for and retrieving items from shelving. Vertical carousels and VLMs, because of their vertical design, have the added benefit of taking advantage of unused overhead space for storage. This recovers up to 75 percent floor space required by traditional shelving, freeing that space for more value-added operations. Horizontal carousels traditionally provide higher throughput, up to 50 percent floor space savings and a lower acquisition cost.

For many operations, a combination of these methodologies provides an efficient solution to achieving maximum flexibility in the kitting strategy. For example, by integrating inventory management software such as FastPic4 with fully automated vertical carousels, VLMs and pick-to-light systems users can achieve a high level of productivity and system throughput while significantly improving picking accuracy. In some manufacturing applications, the integration of inventory management and control software with automated storage and retrieval systems has resulted in a 50 to 60 percent improvement in productivity and a 99.99 percent accuracy level.

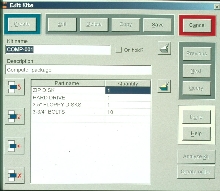

FastPic4 software offers a special kitting interface that includes an easy-to-use grid field, similar to a spreadsheet that streamlines data entry by allowing users to easily fill in the SKU number and the quantity of each to create a bill of materials. Text is fully customizable, allowing the use of common or industry-specific names of components rather than part numbers if desired. To retrieve a kit, an operator simply enters the bill of materials identifying number or description and either printed pick lists are generated for manual systems or the

storage and retrieval system automatically directs the operator to pick the correct quantities of the proper items. Features such as bar code scanning add more speed and accuracy to automated storage and retrieval systems.

"Parts kitting is an easy-to-implement strategy that can help organizations improve the efficiency of their operations while improving product and process quality," Card said.