Pressure Sensors / Detectors / Transducers

Innovative Diaphragm Coating for Sensor Resists Highly Abrasive Nickel Ore Slurry

Avoids costly downtime caused by pressure sensor failure

WARMINSTER, PA, October 7, 2009 - Highly abrasive nickel ore slurry flow at a Canadian Xstrata nickel ore processing mill caused serious erosion of metallic diaphragms in pressure transmitters -- even when retofitted with a protective rubber pad. Transmitters failed unpredictably and frequently, requiring replacement once or twice a year. Cost to the mill was thousands of dollars per hour in unscheduled downtime, plus costs for transmitter replacements.

To minimize transmitter failures, Xstrata accepted a promising solution from ABB Instrumentation in Canada. ABB made the mill a beta site for a trial installation of an ABB pressure transmitter having a measuring diaphragm protected with an innovative coating called Diaflex.

Processing nickel ore

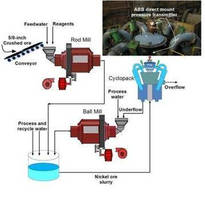

At its mill in Onaping, Ontario, Xstrata Nickel operates five ore processing lines, each producing nickel ore fines. The schematic diagram summarizes ore grinding and separation steps involved in each.

A grinding circuit contains a process unit called a Cyclopack that receives nickel ore slurry, separating out oversized ore particles for recycling and further grinding. A Cyclopack consists of a group of hydrocyclones arranged in a circle to share the ore separation task. Nickel ore slurry to be separated flows to the top of the unit, where it is evenly distributed to the hydrocyclones.

Slurry pressure measured at this location guides mill operators in turning individual cyclones on or off. If the pressure is too high, they add hydrocyclones to maintain desired pressure values and vice versa.

Trial results

In the trial installation, the mill replaced an existing transmitter with an ABB 264 direct flange-mounted pressure transmitter (2600T series) with a Diaflex-coated diaphragm. For this trial test, no rubber pad was added.

Diaflex has exceptional resistance to abrasion, being composed of silicon and titanium combined as a nitride, SiTiN. Using a special deposition process, ABB coats a 316 stainless steel diaphragm with Diaflex to a thickness of 3 to 5 µm.

The ABB pressure sensor operated for more than two years with no sign of diaphragm deterioration. As a result Xstrata has converted the other four Cyclopacks to the test-proven ABB pressure transmitter. The mill is also testing Diaflex-coated diaphragms on other tough and demanding transmitter applications.

ABB (www.abb.com) is a leader in power and automation technologies that enable utility and industry customers to improve their performance while lowering environmental impact. The ABB Group of companies operates in around 100 countries and employs about 120,000 people.

For more information please contact:

ABB Instrumentation

Rob Mapleston

Tel: 1-215-674-6580 or 1-800-829-6001

robert.mapleston@us.abb.com

www.abb.com/instrumentation