Injection Molding Presses deliver rubber part uniformity.

Press Release Summary:

By utilizing Isothermould(TM) distributed power rods in press platens, G9 and G8 injection presses can consistently maintain temperature uniformity at better than ±3° across entire surface of mold. Size and placement of rods near parting line on standard mold configurations also serves to reduce cure times as well as part characteristic variances. In some instances, uniformity is better than ±1.5° in every mold cavity.

Original Press Release:

REP Offers Isothermould(TM) as New Concept in Mold Design

REP, the leader in rubber and TPE injection press technology, announces the inclusion of Isothermould distributed power rods on all its standard injection presses.

Quality rubber parts require optimum uniformity in cure time and mold temperature. Variations in mold temperature, whether in-cavity or at the parting line, result in poor and inconsistent parts or a tendency to overcure to compensate, with attendant power consumption costs.

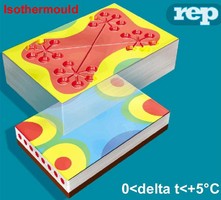

REP has developed Isothermould distributed power rods as a solution. Through exhaustive R&D on heat dispersion and dissipation in various computer and actual mold models, REP determined the ideal size and location of these power rods, in proximity to the parting line on most standard mold configurations.

By use of Isothermould distributed power rods in the press platens, temperature uniformity can be consistently maintained at better than ±3° across the entire surface of a mold. In some case studies, uniformity was better than ±1.5° in every mold cavity. Cure time reductions up to 20% were also reported in these case studies, as was an outstanding 40% reduction in part characteristic variances.

REP now offers Isothermould as standard on all G9 and G8 presses. Retrofit onto existing presses in-plant is also available with very short-term cost recapture. Please contact REP for details and literature.

For more information, please contact: REP CORPORATION, 8N470 Tameling Court, Bartlett, IL 60103. Phone: 847-697-7210. Fax: 847-697-6829. Web: www.rep.tm.fr. Email: repmail@repcorp.com. Attention: Tim Graham.