Injection Molding Compounds resist impacts, chemicals, and fires.

Share:

Press Release Summary:

Fire rated Kydex(R) compounds include 10 injection molding and 20 extrusion grades carrying fire ratings of UL Std 94 V-0/5V, FAR 25.853 (a) and (d), ASTM E-162, ASTM E-84, UL 723, UL 2043, UL 756C and/or Class 1/A. Also available are UL 705-rated grades meeting above-the-ceiling air plenum smoke release requirements. Compounds have impact resistance to 18 ft-lb/in., tensile strength to 6500 psi, flexural strength to 9400 psi, and flexural modulus to 326,000 psi.

Fire rated Kydex(R) compounds include 10 injection molding and 20 extrusion grades carrying fire ratings of UL Std 94 V-0/5V, FAR 25.853 (a) and (d), ASTM E-162, ASTM E-84, UL 723, UL 2043, UL 756C and/or Class 1/A. Also available are UL 705-rated grades meeting above-the-ceiling air plenum smoke release requirements. Compounds have impact resistance to 18 ft-lb/in., tensile strength to 6500 psi, flexural strength to 9400 psi, and flexural modulus to 326,000 psi. Original Press Release:

Kydex(R) Fire Rated, Impact Resistant Compounds Marketed Internationally

MOUNTLAUREL, NJ-KYDEX(R) fire rated, impact and chemical resistant compounds for injection molding and extrusion will be marketed internationally as of May 2002 by maker Kleerdex Company, according to business development manager/compounds Thomas Pugh.

The line is comprised of 10 injection molding and 20 extrusion grades carrying fire ratings of UL Std 94 V-0/5V, FAR 25.853 (a) and (d), ASTM E-162, ASTM E-84, UL 723, UL 2043, UL 756C and/or Class 1/A. Also available are UL 705-rated grades meeting stringent "above- the-ceiling" air plenum smoke release requirements.

These engineering plastics exhibit a range of outstanding physical and electrical properties including: impact resistance to 18 ft-lbs/in, tensile strength to 6500 psi, flexural strength to 9400 psi, and flexural modulus to 326,000 psi. Depending on grade, they are also said to be more resistant to a wider range of concentrated chemicals than any other thermoplastic.

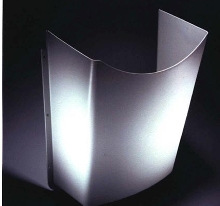

The compounds require no drying and are available in 34 standard colors in low minimums depending on grade, as well as in developed and custom colors including new stainless steel, aluminum, brass, copper and gold metallic colors.

They are derived from the company's line of damage-resistant sheet products marketed worldwide in 50 grades, 10 surface textures and 2000 colors for thermoforming, membrane pressing, and laminating applications. Comparable ratings, properties and colors of sheet and compound grades enable manufacturers to thermoform parts rapidly, in low volumes at low cost, until volume requirements justify injection mold tooling.

Manufactured in Bloomsburg, Pennsylvania to ISO 9002 and 14001 quality standards, the compounds will be marketed as high performance, cost effective alternatives to PC, PPO, PC/ABS and other flame retardant resins for industrial, electrical, building product, telecommunication, aircraft and mass transit applications.

Request literature, samples and engineering assistance from Kleerdex Company, 100 Gaither Drive, Mount Laurel, NJ 08054, Tel: 800-541-7232, ext 209; Fax: 609-866-9728, E- mail: info@kleerdex.com, Web: www.kydex.com