Induction Hardened Rack Gears combine precision, strength.

Press Release Summary:

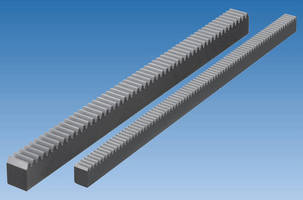

Designed for use in pinion (spur gear) mechanisms, Induction Hardened Rack Gears feature 1045 Carbon Steel construction and create linear actuator that converts rotational motion of pinion into linear motion. RGEAH (Ground) gears offer no hole, bottom tapped, side tapped, or side counterboard tapped hole machining options, while RGEAHL (Ground, Hole Position Configurable) gears offer user-configurable hole machining with bottom, side, or side counterboard tapped options.

Original Press Release:

MISUMI's New Induction Hardened Rack Gears Provide High Precision Combined with Superior Strength and Abrasion Resistance

Expanded product line means more rugged choices for designers of machine tools, conveyors, drives, hoists and other industrial automation and motion control equipment.

(Schaumburg, IL) - MISUMI USA, Inc., a subsidiary of MISUMI Corporation, part of MISUMI Group, Inc. (Tokyo: 9962), has introduced two Induction Hardened Rack Gears to its motion control product lines. The new Rack Gears feature 1045 Carbon Steel construction and induction hardened teeth to provide high precision operation, as well as excellent strength and abrasion resistance for long service life.

The Rack Gears are designed for use in pinion (spur gear) mechanisms to create a simple linear actuator that converts the rotational motion of the pinion into linear motion. Used extensively in the automotive, construction and industrial equipment manufacturing industries, rack gears can be found in a broad range of products, including machine tools, conveyor systems, hoists, drives, roller feeds and more.

MISUMI's new additions to its rack gear line include:

Both new rack gears are manufactured in 1045 Carbon Steel with Black Oxide Finish, and both feature end face machining. The Rack Gears are available in a variety of sizes (Module 1.0, 1.5, 2.0, 2.5 and 3.0). Shipping times range from three (3) to six (6) days, depending on which type and hole machining options are selected.

For more information about MISUMI's new Induction Hardened Rack Gears, complete with technical data, pricing and delivery times, please contact MISUMI Customer Service at 1-800-681-7475 or visit our online catalog at us.misumi-ec.com.

About MISUMI USA, Inc.

Located in Schaumburg, Illinois, MISUMI USA, Inc. was established in 1988 as a Subsidiary of MISUMI Corporation, a part of the MISUMI Group (TOKYO: 9962). MISUMI USA, Inc. is a leading supplier of fixed and configurable components such as leader pins, single-axis actuators, linear shafts, slotted keys, aluminum extrusions, parting locks, linear guides, XY stages and other components for factory automation, plastic mold and press die industries. For a complete list of available components, please visit MISUMI USA.