Impeller Blade is made of aluminum C355 material.

Press Release Summary:

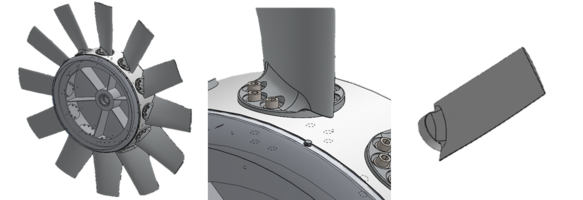

Impeller Blade is suitable for axial fans and weighs 47 lbs. Unit comes in a length of 32.5 in. and is suitable for underground and above-ground mining and power industry applications.

Original Press Release:

MES, Inc., Introduces One-Of-A-Kind Impeller Blade Casting

MES, Inc., the worldwide leader in global manufacturing resources and supply chain management, recently delivered a unique product to a customer that required a heat-resistant blade for axial fans.

The customer chose Aluminum C355 for the blade material for several reasons. Aluminum C355 is ideal for casting and offers excellent pressure tightness and resistance to cracking from heat. The material also possesses optimal fluidity and allows for excellent welding strength, although that trait was not required for this particular application. Aluminum C355 can be polished to a high shine, making it look attractive in highly engineered products. The impeller blade in this case was cast for use in underground and above-ground mining and power industries.

The casting process required several rounds of testing, quenching, and reforming. The material was cast using a high-vacuum melting casting furnace and high-tilt automatic equipment. The customer then required X-Ray testing per ASTM E155 because some areas needed to meet Level 2 while others needed to meet Level 4. Near the shank of the blade, parts were machined with tight tolerance of +/-0.02, and all parts needed to be T6 heat-treated.

The final product weighed 47 pounds after an initial cast weight of 52 pounds. The blade has an overall length of 32.5” and a blade length of 30.6”. No distortions were allowed along the trailing edge, the O.D. of the shank area had to be properly filled, and the whole piece had to meet an elongation requirement of 8% while also meeting T6 mechanical properties.

“There were many nuances to this project,” said Hiten Shah, MES President. “The guidelines did not allow for flexibility and everything had to be done with the utmost care. The end product reflects the high quality of work customers can expect from MES, Inc., on a global scale.

Learn more about MES, Inc., at www.mesinc.net.