I/O Module interfaces automated production lines and LINbus.

Press Release Summary:

Designed for fixed installation on DINrail or in control cabinet, LIN I/O provides interface between automated production lines and LINbus product. Adapter communicates remotely with controller via CAN/24 V DIO and can independently carry out simple sequences. Enabling test device communication via LIN I/O in safe, short-circuit protected manner, product also features internal signal processing of LIN data as well as measurement of current drain for test object.

Original Press Release:

Saelig Introduces LINbus I/O Module

LIN I/O is an interface between automated production lines and a LINbus product

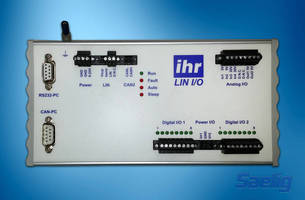

Fairport, NY – Saelig Company, Inc. announces the availability of LIN I/O - a communication adapter designed as an interface between automated production lines and a LINbus product. Designed for fixed installation on a DINrail or in a control cabinet, LIN I/O communicates remotely with a controller either via high-speed CAN and/or 24V digital I/O. Using the LIN I/O, a test device can be communicated via the LIN I/O communications in a safe, short-circuit protected manner.

A unique feature of the LIN I/O is that the current drain of the test object is measured and can be used for evaluation and test purposes. The LIN I/O's internal signal processing can pre-process the LIN data, for example for checking limit values or operation, or for the end-of-line calibration of manufactured devices. The control and automation software can thus be freed up, and the LIN interface can independently carry out simple sequences and deliver - for example - "good/bad" evaluations to the manufacturing line. The LIN I/O module is compatible with the other members of IHR's family of automotive bus tools.

Performance Characteristics of LIN I/O:

- Emulation and Analysis of LIN nodes / LIN subsystems, simulation of bus devices not present

- Wakeup / Sleep

- Event-based signal configuration and sequence control

- LIN bus error recognition, playback via CAN, LED and port

- Uses Visulin PC software for recording and displaying measurement data, and for configuration

- Simple integration into automated test environments (LabView, HP VEE, and others)

Equipment:

- Status display via LED's

- Ohmic bus termination (master/slave/stress/overload) switchable by means of software

- Galvanically separated digital inputs/outputs

- LED status display for digital ports

- 4 analog inputs

- 2 analog outputs, trigger creation

- 1 current measurement channel for current drain of the test object

Optional Accessories:

- Second CAN interface for vehicle bus

- CAN I/O peripheral extension

Made in Germany by IHR (one of - Europe's major CAN and LIN experts) LIN I/O is available now from their authorized USA distributors Saelig Co. Inc. Fairport, NY. For detailed specifications, free technical assistance, or additional information, please contact Saelig 888-7SAELIG, via email: info@saelig.com, or visit www.saelig.com.

About Saelig Company Inc.

Founded in 1988 in Rochester, New York, Saelig is a North American distributor with a growing reputation for finding and sourcing remarkable, unique test and measurement and control products and components for use in a wide variety of industries. Products lines are continuously added from sources across the globe, and are offered at competitive prices, accompanied by full in-house technical support, exceptional customer service, and fast delivery. For full details of available product lines, please visit www.saelig.com.