Hydraulic Power Chuck suits hard turning applications.

Press Release Summary:

Operating at speeds to 7,000 rpm, GHA6-8-66 consists of one 8 in., 3-jaw chuck with 66 mm through hole. Clamping repeatability is less than 10 microns. Additional offerings include proprietary and Matsumoto hydraulic power chucks, cylinders, and wheel chucks; rotary tables for single- and multiple-axis CNC machinery; Atling steady rests; and Neidlein face drivers. Unit permits machining at feed rates required for cutting aluminum and is suited for machining steel.

Operating at speeds to 7,000 rpm, GHA6-8-66 consists of one 8 in., 3-jaw chuck with 66 mm through hole. Clamping repeatability is less than 10 microns. Additional offerings include proprietary and Matsumoto hydraulic power chucks, cylinders, and wheel chucks; rotary tables for single- and multiple-axis CNC machinery; Atling steady rests; and Neidlein face drivers. Unit permits machining at feed rates required for cutting aluminum and is suited for machining steel.Original Press Release:

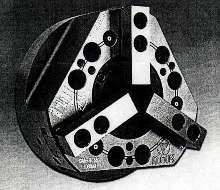

Eight Inch Hydraulic Power Chuck with Larger Through Hole Offers High Speed (7000 RPM) Needed for Hard Turning Applications

Logansport, IN - Logansport Matsumoto Company's Model GHA6-8-66 hydraulic power chuck operates at 7000 RPM. It permits machining at the high speeds and feeds required for cutting aluminum, and is ideal for machining steel, especially in hard turning applications.

The GHA6-8-66 is a big bore, 8-inch, three-jaw chuck with a 66 mm through hole. This compares to a standard 52 mm through hole for this size chuck. The 66 mm through hole allows the user to chuck larger parts or bar feed a larger diameter bar.

Clamping repeatability is less than 10 microns. This high level of precision allows the user to clamp parts with greater accuracy. Thus, the manufacturer will be able to produce more accurate, more consistent and better quality parts when compared to equipment without this level of repeatability.

The LMC Workholding line includes...

- LMC and Matsumoto hydraulic power chucks, cylinders and wheel chucks;

- LMC rotary tables for single & multiple axis CNC machinery, EDM and other machining applications;

- Atling steady rests;

- Neidlein face drivers, as well as live and dead centers.

Contact Logansport Matsumoto Company, PO Box 7006, Logansport, IN 46947-7006, telephone 574-735-0225, fax 574-722-6559. E-mail: info@logan-mmk.com

Website: www.logan-mmk.com.