Hybrid Moldable Foam Resin offers heat resistance.

Share:

Press Release Summary:

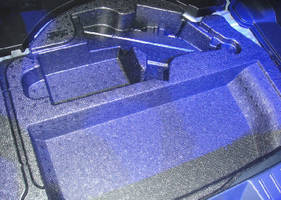

Consisting of styrenic and olefin components, Piocelan® T Foam Grade offers elevated temperature stability and is engineered to meet stringent flammability requirements for automotive interior parts. Foam parts designed and molded using Piocelan T, such as trunk spacers and insert cushions, offer advantages over parts made with existing hybrid foam materials, including weight and size reduction.

Original Press Release:

Sekisui Plastics USA Introduces a New Heat-Resistant Piocelan® Foam Grade

MT. PLEASANT, TN USA - Sekisui Plastics USA has introduced a new grade of Piocelan® moldable foam resin. A hybrid of styrenic and olefin components, the new Piocelan T is composed of a higher heat olefin component than previous grades, offering increased elevated temperature stability along with higher compressive, flexural and tensile strength. It is engineered to meet the stringent flammability requirements for automotive interior parts.

“Existing hybrid foam materials provide insufficient heat resistance for certain automotive interior applications,” said Thomas Pontiff, Vice President of Sekisui Plastics USA. “This new hybrid composition uses a different olefin which provides heat resistance and improved physical and flammability properties over other hybrid foam grades and materials used for automotive and industrial foam parts.”

Developed after extensive research efforts using Sekisui Plastics’ proprietary polystyrene/polyolefin hybrid foam technology, Piocelan T uses a polyolefin type that is difficult to expand together with polystyrene because of drastically different viscosities at molten temperatures. “We use a unique processing technique to produce and expand the hybrid composition,” said Pontiff. “This technique yields foam beads that are easily molded into foam parts that have an exceptional combination of properties.”

Foam parts designed and molded using Piocelan T, such as trunk spacers and insert cushions, offer a number of advantages over parts made with existing hybrid foam materials. “For example,” said Pontiff, “Part weight can be reduced by approximately 20-40% resulting in lower vehicular mass, which contributes to fuel economy and the environment.  Part size can also be reduced because of the higher strength properties, which contribute to a more spacious interior in the automobile. And, because a lower mass of foam material is needed, due to lower foam density and reduced part size, part cost can be reduced.”

Because the production of Piocelan T requires a slightly different processing technique than previous Piocelan grades, Sekisui recently completed the necessary process upgrades and improvements at its resin production facility in Tennessee. “Since Piocelan will be manufactured in the U.S. turnaround time will be significantly reduced,” said Pontiff. Sekisui also installed molding capability for Piocelan T at its Tennessee molding facility and is planning to install the same capability at its new Kenton, Ohio plant set to begin operations in the spring of 2015.

For more information, contact Sekisui Plastics USA, Inc. by calling 931-379-0300 or visiting www.sekisuiplastics.com.