Horizontal Tray Former produces 2,700 trays per hour.

Share:

Press Release Summary:

Fully automatic TF 600H produces trays that facilitate handling, storage, and shipment of products on standardized pallets. Product also allows for mixed pallet loads with production of common footprint trays. Capable of producing hundreds of tray styles, unit produces 600 x 400, 400 x 300, and 500 x 400 mm footprint trays, with various depths. Trays conform to 5 and 6 down requirements, while 10 and 12 down half sizes can also be produced.

Original Press Release:

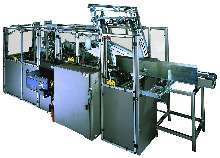

New TF 600H Horizontal Tray Former

Mechanically Simple, High Speed, Hundreds of Tray Designs

(Reedley, CA) - SWF Companies' new TF 600H horizontal tray former is a fully automatic forming solution for hundreds of tray designs, including common footprint trays, and is capable of producing up to 2700 trays per hour.

Ideally suited for today's produce industry, the TF 600H produces trays designed to facilitate the handling, storage and shipment of produce and other products on standardized pallets. Mixed pallets (various types of products on a single pallet) are also possible with common footprint tray designs and allow trays from multiple manufacturers to interlock and stack together, while easily fitting into most in-store refrigeration systems.

Furthermore, the TF 600H is capable of producing an extensive array of other tray designs that may require a horizontal tray forming solution. Such tray designs include one-piece laminated corner posts, display style and design style trays.

SWF's TF 600H produces (with long dimension first) 600 x 400, 400 x 300 and 500 x 400 mm footprint sized trays. All three sizes can have various depths, conform to the 5 and 6 down requirements, while 10 and 12 down half sizes can also be produced. Common footprint machinery and the corresponding tray designs are the result of establishing a Corrugated Product Container Modularity Standard (sponsored by the Fibre Box Association).

Standard features on the TF 600H include a mechanically simple design, variable frequency drive, Kwik-change controls, Nordson hot melt glue system, ultra-view guarding, large capacity hopper and PLC controls. Numerous options are also offered on the TF 600H to further meet the specific needs of each customer. In addition to producing hundreds of tray designs, down stream controls, tray stacking attachment and a laminating section are also available options on the TF 600H.

SWF Companies:

For well over 50 years, SWF Companies has been providing innovative packaging automation solutions worldwide. Located in Reedley, CA, SWF offers an extensive array of products including tray, bliss and RSC formers / sealers, case packers, vertical / horizontal cartoners and flexible bag packers. Our Global Technical Support team and Automation Solutions Group provide industry-leading customer service.