High-Pressure Valves provide positive leak-free shut-off.

Press Release Summary:

Co-ax(R) valves are available for pressures up to 7,500 psi, actuation speeds of 30 msec, and in wide range of sizes, seal and construction materials. They handle high pressure applications, such as gas turbine fuel systems, cylinder filling, cryogenic pumps and vacuum furnace quench gas supply systems. Units come in 2/3- and 3/2-way versions, and in normally-opened or normally-closed configurations. Standard orifice sizes range from 2 to 15 mm.

Co-ax(R) valves are available for pressures up to 7,500 psi, actuation speeds of 30 msec, and in wide range of sizes, seal and construction materials. They handle high pressure applications, such as gas turbine fuel systems, cylinder filling, cryogenic pumps and vacuum furnace quench gas supply systems. Units come in 2/3- and 3/2-way versions, and in normally-opened or normally-closed configurations. Standard orifice sizes range from 2 to 15 mm.Original Press Release:

High Performance Valves For High Pressure Applications

Penndel, PA, December 2001 - One of the Greatest challenges in high-pressure flow system design is finding the right valves. The performance of most traditional valve types - in terms of cycle speed, operating precision and operational life - is severely affected by elevated operating pressures.

High-pressure differentials cause valves to cycle more slowly and erratically, with poor and imprecise shutoffs. The high pressures also accelerate valve wear, further exacerbating repeatability problems.

All these concerns are further compounded by the level of precision and dependability that so many high-pressure systems demand.

In applications like gas turbine fuel systems or vacuum furnace quench gas supply systems, a shutoff valve that's a fraction of a second too slow can cause major damage to a multi-million dollar installation. In other applications, such as cylinder filling, systems and cryogenic pumps, a poor-performing dispensing or relief valve can be as dangerous as it is expensive. And then there are applications similar to the end-of-loop- valves on RIMM systems, where a valve must cope with both high pressures and difficult to handle fluids (isocyanate).

For applications like these, a true high-pressure valve design is essential. And many design engineers have found that the co-ax® valve configuration is the best suited to the task. co-ax® valves were originally developed to solve the demands of difficult applications where positive shutoff and repeatable actuation sped over a long cycle life is critical.

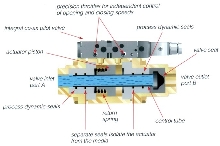

Today, the descendants of these original co-ax® coaxial valves are being used in a broad range of applications worldwide -successfully handling system pressures up to 500 bar (7,500 psi) while delivering millions of precise, repeatable cycles at actuation speeds as rapid as 30 milliseconds. The reason why co-ax® valves perform so flawless under extreme pressures is that co-ax operation is totally pressure-independent. In a co-ax valve, media flows straight through the valve without deviation. This coaxial flow allows pressures to remain almost perfectly balanced on both sides of the valve actuator. Regardless of- how high operational pressures go. differential pressures (which usually negatively affect valve speed and repeatability are nearly non-existent.

This unique design allows the co-ax® valves to cycle more quickly, with positive, leak-free shutoffs. Actuation requirements are minimized, as are operational stresses on valve that has only a single moving part. The coaxial design means there is no deviation in flow path - allowing even highly viscous fluids to pass through the valve easily. Indeed, the straight-through flow actually scours the valve clean, preventing build-ups that could otherwise cause wear, flow and shutoff problems.

As a result, co-ax® valves can last up to ten times longer than conventional valves in high pressure applications, while requiring virtually no maintenance throughout their extended life cycles.

In addition to performance, the coaxial configuration has additional benefits that simplify the valve's integration into new- or existing machines. The pressure-balanced design reduces actuation requirements, and therefore actuator and valve size.

Available in a wide range of sizes, configurations, seal and construction materials, each high-pressure co-ax® valve is virtually designed to the application. For example, co-ax® offers both direct acting and externally controlled models, all of which may be specified in 2/3 and 3/2 way versions with normally-opened or normally-closed configurations. co-ax® high pressure valves are also available in lateral valve configurations. Standard orifice sizes range from 2 - 15 mm, with many other sizes available. With this level of design flexibility, compact co-ax® valves can easily replace virtually any conventional valve type.