Heatstaking Press features integrated dual power supplies.

Press Release Summary:

400 Series heatstaking press features two-position pneumatic slide table, quick change tooling assembly and digital electronic programmable pressure regulator. Six-zone temperature controlling power supply and Thermasoft temperature controlling software provide remote control of up to 480 individual temperature zones. Multi-Job storage component allows instant recall of up to 99 individually stored programs.

400 Series heatstaking press features two-position pneumatic slide table, quick change tooling assembly and digital electronic programmable pressure regulator. Six-zone temperature controlling power supply and Thermasoft temperature controlling software provide remote control of up to 480 individual temperature zones. Multi-Job storage component allows instant recall of up to 99 individually stored programs.Original Press Release:

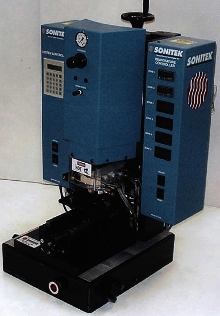

Sonitek Corporation Introduces New High Precision Heatstaking Press

Sonitek Corporation, located at 84 Research Drive in Milford, CT, announces the addition of a new high precision heatstaking press to compliment their product line of plastic assembly machines.

The new 400 series press is smaller than Sonitek's existing line of heatstakers. It takes up less space in assembly area, and features Integrated Dual Power supplies for total control of the assembly operation.

"Because of many manufactures concerns for their employees safety, features have been added to this machine to keep operators protected." Said Robert Bishop, President and

Founder of Sonitek. Opto-touch palm buttons help reduce operator fatigue and reduce the chance of carpal tunnel syndrome, and an integrated 2-position pneumatic slide table allows for part assembly, load and unloading out and away from heated tooling.

Other features have been added for maximum efficiency and minimum error. The new machine features a six-zone temperature controlling power supply as well as Thermasoft(R) temperature controlling software for remote control of up to 480 individual

temperature zones. In addition, if the machine temperatures move outside of the pre-set temperature range, alarms will prevent the machine from cycling. This feature is programmable with ranges of 1-degree increments. A Multi-Job storage component

allows for instant recall of up to 99 individually stored programs.

The new machine is also equipped with a quick-change feature for the upper tooling assembly. This feature allows the operator to change the head assembly with no need for extra tools, and allows the technician to change the head assembly even while hot. Also available is a 'new flow' post cooling kit, which cools heated tips prior to the head retracting and 'sets up' semi-crystalline materials to ensure of tight, molded look stakes. Hydraulic speed controls provide repeatable stroke speed for head down operations.

Digital Electronic programmable pressure regulator is integrated into the machine and will prevent the machine from cycling due to air loss or gain. Electronic dual cells measure forces during a staking or insertion cycle and electronic lower encoders provide either incremental or absolute distance control to +/-.0001". The system also features self-diagnostic circuitry. Other options include: Pre-Heat option for installing inserts - Eliminates hoop stress and prevents "cold" press of inserts into plastic, Ethernet communications, system controller for 'plug and play' optional add-ons, and OPC server software.

This product is especially efficient for manufactures that require a safe, clean, reliable method of assembly. These machines will sell in the range of $2,500 - $4,800 not including tooling. Tooling starts at $35.00 and typically averages a few hundred dollars depending on the complexity of the application.