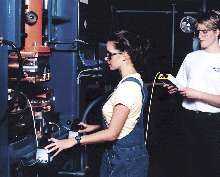

Hand-Held Weld Monitor is battery operated and portable.

Share:

Press Release Summary:

Model MX 321 can be used for spot testing of welding operations or can be attached to welding equipment for continuous performance monitoring. Weighing 1.5 lbs, unit can simultaneously display any 3 of the following: IRMS, IRMS Max, Weld Cycles, POS Peak, Half Cycles, NEG Peak, and Conduction Angle. It measures AC and DC with weld current detection (+2%) of: 0-5, 2-20, and 10-100 kA. Unit also provides programmable spot counter and error signaling.

Original Press Release:

New Weld Monitor Portable Unit Does More Yet Costs Less

(Bay City, MI) --- Production Support Services, Inc. introduces the MX 321, a portable hand-held monitor that can be used either for spot testing of welding operations or, attached to welding equipment, for continuous performance monitoring. Compact and light-weight (just 1.5 lbs.), the MX 321 is priced significantly lower than competitive weld monitoring devices. Yet it offers a variety of functions to enhance both quality and productivity in automated welding systems.

One such feature is the ability to display simultaneously any three of the following:

o IRMS, IRMS Max o Weld Cycles

o POS Peak o Half Cycles

o NEG Peak o Conduction Angle (25º - 180º)

With the MX 321 monitor, the welding operator can quickly set tolerance parameters for weld quality purposes. When out-of-tolerance conditions occur, the monitor will either sound an alarm or will stop the welding cycle.

"The MX 321 incorporates features that would ordinarily be found in a weld monitor that costs a lot more," says Bob Dickie, president of Production Support Services, Inc. "It is geared towards improving both product quality and the productivity of the welding process."

The MX 321 is powered by a rechargeable battery with a 12-hour life and automatic shut-off after 30 minutes of idle time. (The battery charger is included with purchase.) It also has RS 232 output for easy connection with most computer systems and with an optional portable printer. It measures AC and DC with weld current detection (±2%) of: 0 - 5kA; 2kA - 20kA; and 10kA - 100kA.

Other key features include: weld time measurement (0 - 100 cycles); measurement of effective maximum value reached in weld cycle; measurement of effective weld current in entire weld cycle; error signaling through buzzer and relay contact for out-of-tolerance weld; and, programmable spot counter for electrode life monitoring.

Production Support Services, Inc. specializes in providing parts, service, and standard machines for automated manufacturing systems to appliance, automotive, office furniture, and other manufacturers.