Grooving Tools feature reinforced blades. .

Press Release Summary:

With dual internal coolant delivery system, Walter Cut G2042 Series optimizes surface finish in parting and grooving operations. System precisely delivers coolant to flank and to chipbreaker of insert, resulting in constant optimum operating temperature. Parting blades come in sizes of 1.02 and 1.26 in., and inserts are available in widths of 2–4 mm. Prime applications include turret turning centers with bar feeders parting off to center and performing depths of cut greater than 0.315 in.

Original Press Release:

The Walter Cut G2042 Improves Grooving and Parting Operations

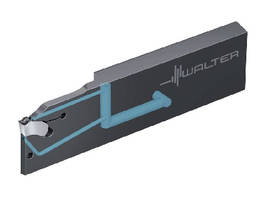

With reinforced blades and a dual internal coolant delivery system the Walter Cut G2042 tools improve surface finish and heighten process reliability in parting and grooving operations.

Waukesha, WIÂ – Walter has introduced the Walter Cut G2042 series of grooving tools, featuring reinforced blades and a dual internal coolant delivery system. In grooving and parting off operations, cutting edges are exposed to high mechanical and thermal stresses. Effective cooling and lubrication is imperative.

The G2042 system precisely delivers coolant to the flank and to the chipbreaker of the insert. The result: A constant optimum operating temperature with the coolant stream targeting the center of the chip formation. This leads to better chip control, which in turn produces improved surface finishes and flatness and better tool life.

The Walter Cut G2042 parting blades with precision cooling are available in blade sizes of 1.02 in. and 1.26 in. (26-32 mm). Inserts for the G2042 are available in widths of 2-4 mm. Prime target applications include turret turning centers with bar feeders parting off to center and performing depths of cut greater than 0.315 in. (8 mm), particularly on difficult to machine materials, especially high temperature alloy materials.Â

Walter, a global leader in the metalworking industry with over 90 years of experience in precision cutting tools for milling, drilling, turning, boring and specialized tools, helps customers improve process reliability and increase productivity. With Regional Headquarters in Waukesha, WI, Walter markets its competence brands Walter Valenite, Walter Titex, Walter Prototyp and Walter Multiply through a strong network of distributors and field engineers across subsidiaries in the USA, Canada, Mexico, Brazil and Argentina.