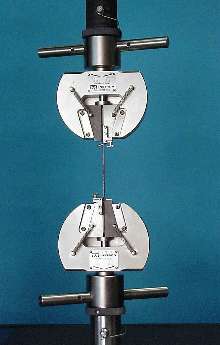

Grips provide specimen loading, alignment, and positioning.

Press Release Summary:

Mechanical Wedge Action Grips are rated at 50 kN and feature fixed faces, movable bodies, and slack-free connection to test instrument. Self-tightening action minimizes slippage and enables operator to apply minimial initial clamping force. Grip faces are spring-loaded in fixed position, so there is no recoil or loosening. Grip frames ensure rapid clamping and unclamping action. Interchangeable jaw faces can test specimens up to 18 mm thick.

Original Press Release:

Instron® Expands its Line of Test System Accessories with New 50 kN Manual Wedge Action Grips

Instron®, a leading provider of testing equipment designed to evaluate mechanical properties of materials and components, offers its new 50 kN rated capacity mechanical wedge action grips. Designed for easy specimen loading, alignment and positioning, these grips are ideally suited for testing high-strength materials such as metals, wire, plastic, elastomers and composites.

Instron's mechanical wedge action grips are designed with fixed faces, movable bodies and slack-free connection to the test instrument. The grip bodies are moved to clamp the specimen without altering the faces' vertical position, which virtually eliminates pre-load buckling during specimen clamping. This wedge action grip design provides a self-tightening action that minimizes slippage and enables the operator to apply minimal initial clamping force to the specimen. This unique design allows a strong clamping force to be applied to materials that are difficult to hold. Grip faces are spring-loaded in a fixed position, so there is no recoil or loosening if the specimen ruptures or if an extensometer is attached.

The open front design of the grip frames ensures quick set-up with rapid clamping and unclamping action. Instron's 50 kN grips come equipped with interchangeable jaw faces that can test specimens up to 18 mm thick. A 5 mm spacer is provided to accommodate a zero gap closing of the faces. Additionally, Instron offers an optional specimen centering device which allows for consistent and repeatable placement of the specimen in the clamping area, to provide increased productivity and valid results.

About Instron

Instron is a leading provider of testing equipment for the material testing and structural testing markets. Instron's products test the mechanical properties and performance of various materials, components and structures in a wide array of environments. A global company providing single-source convenience, Instron is a full-service materials testing company that manufactures and services testing instruments, systems, software and accessories. Instron's proficiency in designing and building testing systems to evaluate materials ranging from the most fragile filament to advanced alloys, affords Instron's customers a broad capability for all their research, quality and service-life testing requirements.

For more information, contact Instron, 100 Royall Street, Canton, MA 02021; 800-564-8378; fax 781-575-5751; email info_news@instron.com. Information is also available on the company's enhanced website at www.instron.com.