Gripper Fingers offer flexible part repositioning.

Press Release Summary:

Rotary fingers for grippers allow 0 to 180 deg part repositioning while part is gripped. They are offered in 4 sizes with output torques from 0.4 to 11 Nm, and will accommodate wide range of parts. Housings are hard-coated aluminum. Double-acting, piston driven rack gear and gear train facilitate actuation while providing repeatable rotation. Thrust bearings support output shaft, and end positions are hydraulically dampened.

Rotary fingers for grippers allow 0 to 180 deg part repositioning while part is gripped. They are offered in 4 sizes with output torques from 0.4 to 11 Nm, and will accommodate wide range of parts. Housings are hard-coated aluminum. Double-acting, piston driven rack gear and gear train facilitate actuation while providing repeatable rotation. Thrust bearings support output shaft, and end positions are hydraulically dampened. Original Press Release:

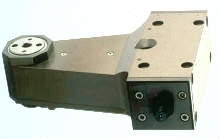

Rotary Fingers for Grippers Offer Flexible Part Repositioning

SCHUNK Precision Workholding Systems has introduced gripper fingers that allow 0 - 180 degree part repositioning while the part is gripped. In applications where parts must be accessed from multiple sides, this flexibility not only saves valuable time, it also reduces cost by eliminating an additional regrip process.

Offered in four sizes with output torques from 0.4 to 11 Nm, these fingers will accommodate a wide range of parts. The slim profile assures minimal interference with other system components, and their low weight guarantees system optimization.

The housings are hard-coated high-strength aluminum. A double-acting piston driven rack gear and gear train facilitate actuation while providing robust repeatable rotation. Robust thrust bearings support the output shaft to assure even rotation and long life even under heavy grip forces. The end positions are hydraulically dampened assuring smooth, repeatable, accurate repetition. Many options for mounting and sensing are also available.