Gas and Chemical Sensors / Detectors

Go Digital – Reaching the Goal More Quickly with Less Effort

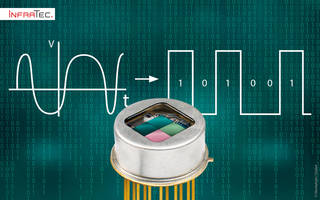

The pyroelectric detector becomes digital and supplements the portfolio of analog detectors.

InfraTec has been developing and producing pyroelectric detectors for over 30 years now. They have been tried and proven for numerous demanding customer applications in recent decades. However, to reduce the expenditure for customers and to facilitate the system integration of a detector, InfraTec has developed the digital pyroelectric detector (LRD).

An overview of the digital detector

Like all detectors from InfraTec, the digital detector is based on lithium tantalate (LiTaO3) and is used in the field of gas analysis and flame detection. It enables complete flexibility in the configuration of the detector parameters and therefore variable signal processing. In addition, it offers improved electromagnetic compatibility (EMC), as the entire signal conversion of the detector is spatially concentrated and shielded. The digital detector offers a wide range of further benefits.

It is equipped with a clock input (pin) to synchronise the radiator and the detector clock. This means that a time signal with a highly precise sampling rate can be generated. An additional, special feature is the „fast recovery after saturation “. This function detects the override due to a defective operating status and automatically resets the analog input stage.

The digital detector converts the analog signal with a 16-Bit resolution directly into a digital signal. The analog signals can be multi-stage adjustably filtered and strengthened. The complete signal processing is performed via an ASIC (application-specific integrated circuit) with integrated A/D-converter, whereby the analog input stage acts like a transimpedance amplifier. Users receive a digital measurement signal, which can be read out via a standard communication interface and processed immediately.

Two completely different detectors

The digital detector will expand the portfolio comprising analog detectors in the future. Which of the two variants is used, depends mainly on the complexity of the measuring tasks. Both detectors have their strengths and offer different benefits.

About InfraTec

The InfraTec infrared sensor and measuring technology company was founded in 1991 and has its headquarters in Dresden, Germany. The privately held company employs more than 200 employees and has its own design, manufacturing and distribution capabilities.

In its infrared sensor division, pyroelectric detectors are developed and manufactured at the headquarters. The product range includes analog single and multi-channel detectors as well as digital multi-channel detectors (PyrIQ). The detectors are used, for example, in gas analysis, fire and flame sensors and spectroscopy.

With its infrared measurement business unit, InfraTec is one of the leading suppliers of commercial thermal imaging technology. In addition to the high-end camera series ImageIR® and the VarioCAM® High Definition series, InfraTec offers turnkey thermographic automation solutions e. g. for industry processes, non-destructive testing and fire detection and prevention.

Contact:

Company address: InfraTec GmbH

Infrarotsensorik und Messtechnik

Gostritzer Str. 61 – 63

01217 Dresden

Phone: +49 351 82876-700

Fax: +49 351 82876-543

E-mail: sensor@InfraTec.de

Internet: www.InfraTec.de