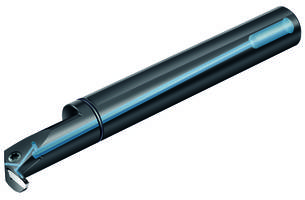

G1221-P Monoblock Boring Bar features UF8 chip geometry.

Press Release Summary:

G1221-P Monoblock Boring Bar features two coolant holes and is designed for recessing and internal grooving. Product is suitable for internal grooves from Dmin = 0.63 in. and for grooving up to depths of 0.39 in. in all ISO material groups. Boring bar is compatible with GX09 and GX16 inserts and insert widths ranging from 0.062 to 0.125 in. G1221-P can be used in normal and overhead position. Unit is attached with O-ring into the bar clamping diameter to prevent pressure loss.

Original Press Release:

The New Walter Cut G1221-P Monoblock Boring Bar Delivers Optimal Cooling for Superior Machining

Walter G1221-P monoblock boring bar provides reliable internal grooving and recessing and superior productivity, surface quality, and tool life.

Walter has unveiled the Walter Cut G1221-P, an innovative grooving boring bar with precision cooling, designed for recessing and internal grooving. This monoblock boring bar has two coolant holes. The first coolant hole allows the coolant to exit the insert top clamp directly to the cutting edge in the radial groove, thus providing precision cooling. The other coolant hole, at the front of the bar, can either be left open to evacuate chips out of a blind bore, or sealed off when in a through-bore to provide increased coolant to the cutting edge.

Additionally, an O-ring is recessed into the bar clamping diameter to prevent pressure loss and provide leak free coolant supply to the cutting interface. This is particularly helpful on machines with low coolant pressure. Together with Walter's new UF8 chip geometry, the combination yields superior process reliability and productivity, excellent surface quality, and longer tool life.

Another advantage of the new Walter Cut G1221-P is that it can be used in both the normal and overhead position. This boring bar system holds GX09 and GX16 inserts. The insert widths go from 0.062 to 0.125 in. (0.8 to 3.5 mm). The system is suitable for internal grooves from Dmin = 0.63 in. (16 mm) and for grooving up to depths of 0.39 in. (10 mm) in all ISO material groups.

Walter, a global leader in the metalworking industry with over 90 years of experience in precision cutting tools for milling, drilling, turning, boring and specialized tools, helps customers improve process reliability and increase productivity. With Regional Headquarters in Waukesha, WI, Walter markets its competence brands Walter Valenite, Walter Titex, Walter Prototyp and Walter Multiply through a strong network of distributors and field engineers across subsidiaries in the USA, Canada, Mexico, Brazil and Argentina.