Foxconn Guadalajara Implements Hentec/RPS Selective Soldering Equipment

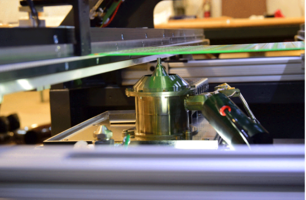

Vector 460 offers unmatched thermal capability, rapid programming, and simplistic elegance in operation.

Newman Lake, WA (April 5, 2021) – Hentec Industries/RPS Automation is pleased to announce that Foxconn Guadalajara has implemented a Hentec/RPS Vector 460 selective soldering system. The Vector 460 is lead-free compatible and features an integrated computer with unlimited program storage, integrated system software, witness camera and auto fiducial correction. Available in either standalone or SMEMA in-line configurations, the Vector 460 is offered with topside preheat, spray or drop-jet fluxer, dual flux nozzles, and custom or wave solder nozzles. The Vector 460 is UL and CE certified and carries both a two-year system warranty and a fouryear solder pot warranty.

“Foxconn Guadalajara chose the Vector 460 from Hentec/RPS because it allowed them to use a manufacturing model to assemble different product types in variable quantities with great efficiency,” said Ron Torenko, of Torenko & Associates.

About Hentec Industries

Hentec Industries/RPS Automation is a manufacturer of automated selective soldering, component lead tinning, and solderability test equipment for electronics and electronic component manufacturing, assembly, and distribution. Hentec/RPS has been advancing automated soldering and lead finishing technology for defense, aerospace, automotive, contract manufacturers and micro-electronics component manufacturers since the early 90’s. All Hentec/RPS products are designed and manufactured in Newman Lake, Washington. For more information, please visit www.rpsautomation.com.

If you would like more information on system sales, please contact:

Tom Baro at 509-385-1228 or tbaro@rpsautomation.com