Force Measuring Instrument has 0.02% F.S. accuracy.

Share:

Press Release Summary:

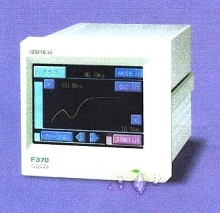

F370 Force Measuring Instrument is offered with full color touch screen displays that allow for setup, calibration, and clear messaging. Displays have adjustable contrast and backlight settings. Weight display changes color as HI-GO-LO limits are reached. F370 provides speeds of 2000 updates per second, and has selectable resolution to 100,000 displayed graduations. Selectable excitation voltages include 2.5, 5.0, and 10.0 V.

F370 Force Measuring Instrument is offered with full color touch screen displays that allow for setup, calibration, and clear messaging. Displays have adjustable contrast and backlight settings. Weight display changes color as HI-GO-LO limits are reached. F370 provides speeds of 2000 updates per second, and has selectable resolution to 100,000 displayed graduations. Selectable excitation voltages include 2.5, 5.0, and 10.0 V. Original Press Release:

F370 Force Measuring Intrument

UNITED CONTROL SYSTEMS, INC. is pleased to announce a new product for the US marketplace, the high speed F370 Force Measuring Instrument.

This unit is one of the first of the new UNIPULSE series instruments being offered with FULL COLOR - TOUCH SCREEN displays. These unique displays allow for easy setup and calibration, clear messaging, and they have adjustable contrast and backlight settings to provide a clear display in any operation area.

The full color display allows for easy user interfaces in many application sites. As an example, on the F370, the weight display changes color as the HI-GO-LO limits are reached. The operator does not have to look away from the weight display to determine if they are in or out of the tolerance windows.

All UNIPULSE instruments are high speed but the F370 is particularly so. With true 2000 updates per second speed, and a selectable resolution of to 100,000 displayed graduations, the

F370 can be used in a wide variety of process control applications.

Full Color Touch Screen - Graphic Display- 2000 updates /sec.

The hi-speed F370 is designed to provide efficient production control functions in a wide variety of applications. The panel mount configuration (DIN 96 size) offers maximum mounting flexibility.

Force, pressure, torque, acceleration, displacement, and flow are just some of the applications that can be supported with this instrument.

Strain gage sensors can be connected directly to the F370, and there are three (2.5, 5.0, and 10.0 V) selectable excitation voltages to provide the correct amount of power for the strain gages in your application.

The touch screen graphic display has three separate display screens available to use at any time. A tracking screen for upper and lower limit comparisons, a peak/valley display to allow for hi-speed response in torque and impact applications, and a graphic "x-y plotting" screen that shows 200 data points in an analog waveform (the minimum time for generating 200 data points is 1/10th second).

The full color, wide view, touch screen can have its display adjusted to fit the application and lighting within the area

of operation. Both contrast and backlighting are adjustable through the front panel.

System accuracy (non-linearity) is 1 part in 5000 divisions (0.02% full scale). Calibration is simple, cycle the front

panel into the calibration mode, press ZERO wait a few seconds to establish a zero reference standard, then enter the millivolt value of the sensor you are calibrating. System dead load (mounting plates, hoppers, etc.) can be compensated for by a dead load weight entry.

Up to 4 separate calibration values (for four separate sensors) can be stored in the F370. This means you can have a pre-calibrated spare sensor in stock should your primary sensor be damaged.

A standard serial communication protocol (SIF) is included with each instrument - the F370 can be matched with UNIPULSE remote displays, and UNIPULSE statistical printers to provide documentation of your application(s). If more communication capabilities are needed then a series of optional Communication Packages are available. These include: RS 232, Analog output (0-10V or 4-20mA), DeviceNet (ODVA approved), CC-Link (Mitsubishi),

BCD, and RS485.