Food Traceability System features touchscreen terminal.

Press Release Summary:

Equipped with touchscreen interface, SIMBA Food and Product Traceability System tracks, labels, and ships unlimited number of products with specific species and characteristics. System automatically generates bills of lading and verifies shipments, eliminating charge-backs. SIMBA also interfaces directly to any scale that has digital output to serial or USB port. Weight of carton is automatically added to database within SIMBA and may be added to label on-the-fly.

Original Press Release:

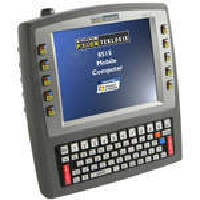

Upgraded Touch Screen Terminals Adds Efficiency to Food Traceability

Redmond - WA -- Dynamic Systems, Inc., a Redmond, Washington software developer specializing in barcode data collection, has announced a larger Touch Screen for The SIMBA Food & Produce Traceability System. SIMBA provides food processors the ability to process, label and track their products from “field to customer”.

Increase productivity speed and traceability

The SIMBA (Specialized Inventory Management with Barcode Accuracy) scale interface solves the problem of how to produce and track complete product labeling for fresh food on the fly.

SIMBA is designed for companies who need fast and accurate information for production and sales. SIMBA tracks, labels and ships an unlimited number of products with specific species and characteristics. The upgraded Touch Screen allows for rapid processing of different species and varieties. The system automatically generates bills of lading and verifies shipments, eliminating charge-backs. SIMBA Enterprise allows the user to track and organize products by pallet, lot and case. Inventory can be tracked by location, allowing moves from warehouse to warehouse, including repeated commingling and re-boxing at any point in the process without losing lot traceability. SIMBA also adheres to the Produce Traceability Initiative requirements (PTI).

SIMBA also now interfaces directly to any scale that has a digital output to a serial or USB port. The weight of the carton is automatically added to the database within SIMBA and may be added to the label on the fly. The ability to have this information automatically can save the producer or packer time when processing and packing a high volume of product.

Results

Key results from implementing the SIMBA software include increased production speed; the ability to get real-time, accurate production reports; ability to fulfill traceability requirements; accurate inventory; professional looking carton and pallet labels; and expedited van loading.

See details at http://www.a-barcode.com/simba/produce-traceability-software

Contact Rob Freeman, robf@dsisales.com, Business Development Manager: 800-342-3999 X 208