Flex EX2 Wireless Controls meet IP66 standards.

Press Release Summary:

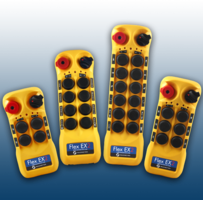

Flex EX2 Wireless Controls are suitable for material handling, overhead crane and industrial applications. The controls’ transmitters are offered in four, six, eight, and 12-button style options whereas the receivers in 4/6 and 8/12 styles. Product features ergonomic design with single thumbscrew for access to batteries and dipswitches.

Original Press Release:

Magnetek Offering Next Generation Flex EX2 Wireless Controls

Magnetek, a leading supplier of digital power and motion control systems for the material handling industry, today announced the availability of their new Flex EX2 wireless controls. These next generation rugged wireless controls are ideal for use in material handling, overhead crane, and industrial applications. Transmitters are available in four, six, eight, and 12-button style options, while receivers will be available in 4/6 and 8/12 styles.

“Flex EX2 wireless controls provide innovative and efficient performance, along with secure and dependable communications,” said Ben Stoller, director of radio controls. “Backed by Magnetek’s expertise and superior service, Flex EX2 is available with new and improved features to enhance safety and efficiency.” The Flex EX2 is versatile, feature-rich, and offers advanced software capabilities, including expanded frequency ranges, channel scanning schemes for anti-interference, drop detection, and remote pairing.

The transmitters feature an improved ergonomic design with a single thumbscrew for easy access to batteries and dipswitches, while retaining its IP66 rating for protection in the harshest indoor or outdoor environments. Also available are a variety of accessories to provide additional protection and flexibility, including protective rubber transmitter boots, a retractable belt clip, and a convenient charging cradle.

For more information about Magnetek’s Flex EX2 wireless controls, visit www.magnetekmh.com.

About Magnetek

Magnetek is a leading provider of Energy Engineered® digital power and motion control systems used in overhead material handling, mobile hydraulic, elevator, and mining applications. The Company is North America’s largest supplier of digital drive systems for industrial cranes, hoists, and monorails and also provides radio remote controls, motors, braking and collision avoidance subsystems to North America’s foremost overhead material handling crane builders. Magnetek provides highly durable wireless controls that can be customized to serve the needs of a variety of applications, including tow trucks, cement trucks, boom trucks, truck cranes, concrete mixers, drill rigs, mining equipment and more. Magnetek is also the world’s largest independent builder of highly integrated digital motion control systems for high-rise, high-speed elevators and is a leading independent supplier of digital motion control systems for underground coal mining applications. Headquartered in Menomonee Falls, Wis., in the greater Milwaukee area, Magnetek operates manufacturing facilities in Bridgeville, Pa., as well as Menomonee Falls. Magnetek is a wholly owned subsidiary of Columbus McKinnon Corporation.