Filtration Media offers high particle capacities.

Press Release Summary:

FATHOM® Liquid Bag Filtration Media is chemically compatible with most liquid applications and does not contain binders that can interfere with fluid. Polypropylene/polyethylene construction is chemically inert, with bi-directional strength and abrasion resistance. Series 500, 510, 520, 530, and 540 provide filtration for particles ranging from 0.5-5, 5-10, 10-25, 25-50, and 50-100 microns, respectively. Engineered gradient density improves efficiency while increasing filter life.

Original Press Release:

Kimberly-Clark Filtration Products Offers Fathom® Liquid Bag Filtration Media

Range of Filter Efficiencies Available With High Particle Capacities

ROSWELL, Ga. - Kimberly-Clark Filtration Products offers FATHOM® Liquid Bag Filtration Media for cleaner fluid streams in applications ranging from food and beverage manufacturing (compliant with FDA 21-CFR), to water treatment, chemical processing, and other scientific and industrial processes.

FATHOM® Liquid Filtration Media is chemically compatible with most liquid applications and does not contain binders that can interfere with fluid - chemistry. Its polypropylene/ polyethylene construction is chemically inert, with excellent bi-directional strength and abrasion resistance. In addition, its fibers are thermally bonded to prevent fiber shedding.

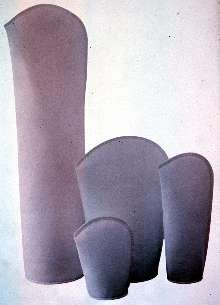

FATHOM® Liquid Bag Media is available in five performance levels designed to deliver the right efficiency to meet specific filtration needs:

o Series 500 - for particles ranging from 0.5 - 5 microns

o Series 510 - for particles ranging from 5 - 10 microns

o Series 520 - for particles ranging from 10 - 25 microns

o Series 530 - for particles ranging from 25 - 50 microns

o Series 540 - for particles ranging from 50 - 100 microns

FATHOM® Liquid Filtration Media has an engineered gradient density - structure designed to improve filtration efficiency in trapping solids from a liquid stream. The fiber density increases through the media from the media upstream to the downstream side. Larger particles are trapped in the upstream

layer, and finer particles are captured in the denser downstream areas, helping to improve efficiency while increasing filter life. Its high particle-holding capacity can translate into longer filter life, fewer filter changes and less downtime.

"The quality of the filtration media used directly affects the quality of the liquids being filtered," explains Ronald C. Cox, Filtration Marketing, Kimberly-Clark. "Inadequate efficiency leaves systems dirty and can impact product quality. Too much efficiency can lead to higher filter costs due to frequent filter changeouts. FATHOM® Media delivers a wide range of efficiencies so users can choose the right media for specific applications."

About Kimberly-Clark Filtration Products

Kimberly-Clark Corporation, a recognized world leader in nonwoven

technology, manufactures a wide variety of filtration media with patented and proprietary technologies. Some of the company's leading filter media products include INTREPID® Filtration Media for HVAC applications; FATHOM®, POWERLOFT®, and CYCLEAN® Filtration Media for liquid filtration applications; and EVOLUTION® Filtration Media laminates for air applications. For more information on Kimberly-Clark Filtration Media, visit www.kcfiltration.com

About Kimberly-Clark Corporation

Kimberly-Clark and its well-known brands are an indispensable part of life for people in more than 150 countries. Every day, one in four people around the world trust Kimberly-Clark's brands to enhance their health, hygiene and well-being - brands such as KLEENEX®, SCOTT®, HUGGIES®, PULL-UPS®, KOTEX®

and DEPEND®. For the second consecutive year, Kimberly-Clark has been named to Fortune Magazine's list of "100 Best Companies to Work for In America." With nearly 64,000 employees worldwide, the company has received similar recognition in the U.K., Argentina, Korea and Thailand. To keep up with the latest Kimberly-Clark news and to learn more about the company's 131-year history of innovation, visit www.kimberly-clark.com.