Extruding System eliminates need for pre-drying/pre-mixing.

Press Release Summary:

Co-rotating, intermeshing twin-screw Series TEM processes plastic compounds, including wood and plastic composites. End product can be directly extruded or pelletized for direct feed to single-screw system. ARIES Process Control System is object-oriented and uses visibility, animation, and touch to perform processing tasks. Stand-alone unit can be swing-arm mounted near line, or mounted elsewhere in plant. Models range from 26-240 mm.

Original Press Release:

NFM To Unveil Wood Processing Technology at NPE 2003

Massillon, OH: NFM, an industry leader in plastic processing systems and equipment, will introduce several new developments in the processing of wood/plastic composite materials at NPE 2003 - Booth 5501. Other plastic processing technologies and the new Aries microprocessor based controller will also be highlighted during the show.

Featured will be NFM's TEM Series of co-rotating, intermeshing compounding twinscrew extrusion system, which offers the highest torque-per-free-volume and highest screw speed of any commercially available system. The TEM Series is capable of processing a wide variety of plastic compounds including wood/plastic composite materials such as PVC, Polyethylene, Polypropylene, in combination with most woods including pine, maple, and oak. The TEM Series is unique in that there is no pre-drying or pre-mixing required saving valuable capital equipment cost, plant space and maintenance. The end product can either be directly extruded from the TEM Series or pelletized for direct

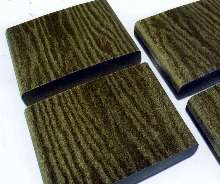

feed to a single screw system. Finished wood products, with their distinctive simulated grain pattern, will be on display for NPE show participants. The TEM Series is available in models ranging from 26mm to 240mm. NFM's new 26mm small production run/laboratory machine will also be on display.

NFM's SPX Series of single-screw plastic extrusion systems will also be represented in their exhibit. The SPX Series is capable of compounding many plastics including wood/plastic composite materials and is available in models ranging from 1½" to 10", and vacuum extruders from 1½" to 8".

Another extrusion technology to be displayed is NFM's Welding Engineers Series of plastic extruders. The WE equipment has a wide variety of applications for devolatilization, reactive extrusion, hot melt adhesives and plastics recycling. The WE Series is a counter-rotating, non-intermeshing twinscrew extruder capable of low shear compounding of long fiber reinforced products. Highlighted will be the WE Series' ability to maintair fiber length during processing which results in improved material properties.

Also being displayed at the NFM NPE Booth will be:

NFM's ARIES Process Control System. This new system is an object-oriented control system using visibility, animation, and touch to perform a wide variety of complex processing tasks. The configuration can operate a complete line like a DCS system at a fraction of the cost. It can be swing-arm mounted so that the operator has complete view of the product, or set up as a stand alone unit nearby the line, or elsewhere in the plant.

The NFM exhibit will also include a section on Laboratory Support Services and Part Development including a high

tungsten carbide twinscrew extruder barrel and extruder head Mono-Clamp for quick die changes and access to extrusion tooling.

For more information about NFM's NPE Exhibit, please contact:

NFM

577 Oberlin Road

Massillon, OH 44647

Phone: 330-837-3868

Fax: 330-837-2230

Web: www.nfm.net

Primary Contact: Paul Roberson

Email: proberson@nfm.net