Extruder reprocesses low bulk density foam.

Press Release Summary:

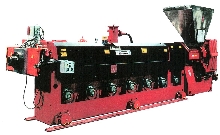

Scrapper(TM) dual-diameter extruder features large diameter screw section equipped with deep flights to mix and break down materials, while small diameter section is dedicated to melting, pumping and removing excess gases and volatiles. Feed section is cored for water-cooling and contains knives to assist in feeding of roll stock. Steel, fixed weldment base allows for mounting of smaller diameter main processing station as well as filtering device.

Original Press Release:

Davis-Standard Scrapper(TM) Simplifies Foam Reclamation

(Pawcatuck, Conn.) - To meet the growing demand for reprocessing low bulk density foam products, Davis-Standard has developed a new version of its highly successful Scrapper(TM) dual-diameter extruder. Davis-Standard has engineered a new feed angle and added supplementary grooves within the feed section to more efficiently process foam products such as meat trays, cups, plates and insulation board. Additionally, the angle of transition between the large and small diameter section of the feedscrew has been customized for this process.

"We have sold several Scrappers for foam reclamation and expect

demand to grow as foam product manufacturing increases," said Steve Kriger, Davis-Standard's Product Manager for Reclaim Systems. "The percentage of scrap from these products is very high and it is one of the most rapidly growing areas in reclaim extrusion."

In addition to low-bulk density products such as foam, the Scrapper is ideal for processing high bulk density material, bags, printed scrap, fiber scrap and scrap on a roll. The Scrapper features several feed assist components that eliminate the cost of shredding, grinding and densification.

The extruder's large diameter screw section is equipped with deep flights tomix and break down materials, while the small diameter section is dedicated to melting, pumping and removing excess gases and volatiles. The feed section is cored for water-cooling and contains removable knives to assist in the feeding of roll stock. A steel, fixed weldment base allows for mounting

of the smaller diameter main processing station, along with any filtering

device.