Etching Process produces high-precision metal parts.

Share:

Press Release Summary:

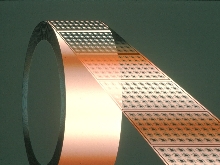

AccuCoil PCM process combines photochemical machining for producing precision burr-free and stress-free metal parts with accurate frame-to-frame indexing on coil stock. It produces intricate and close tolerance patterns in varieties of flat, metal parts with thickness ranges of 0.0005 to 0.062 in. Holes or slots can be as small as 1.2 times material thickness, and spacing between holes or cutouts can be as small as 0.9 times material thickness.

Original Press Release:

New AccuCoil PCM(TM) from Buckbee-Mears Delivers High-Volume Precision Metal Parts

ST. PAUL, MN -- The new AccuCoil PCM(TM) process from Buckbee-Mears Micro- Technology Operations now makes it possible to etch high-precision metal parts on a continuous coil of material for high-volume production. The process combines the advantages of PCM (photochemical machining) for producing groups of precision burr-free and stress-free metal parts, with accurate frame-to- frame indexing on coil stock to facilitate fully automated secondary operations.

"Until now, manufacturers who needed parts with the high precision of photochemical machining on a coil had to rely on manual secondary operations," says Michael Sillmann, Vice President and Managing Director, Buckbee-Mears Europe Operations. "Conversely, manufacturers who needed high-volume metal parts on a coil for automated secondary operations had to rely on expensive dies and roll stamping. Now, manufacturers who need both high-precision and high-volume metal parts on a coil for automated secondary operations can turn to AccuCoil PCM."

The breakthrough accomplished with AccuCoil PCM involves a significant improvement in the frame-to-frame resolution between parts or groups of parts on a continuous roll of material. In photochemical machining, the metal stock is first coated with a photosensitive material that, when exposed to ultraviolet light through a pattern or mask, protects the metal during the etching or chemical machining process. This process is called printing, although no visible image of the parts is produced. In the past, the absence of a visible image made indexing between parts difficult.

"By adapting a new printing technology that accurately indexes one photo mask exposure to the next on the roll, we have been able to achieve frame-to-frame tolerances of ±25 microns in two directions," says Sillmann. "This is an improvement in accuracy over precision roll stamping by a factor at least two."

Sillmann says that nearly all photochemical machining of metal parts involves secondary operations such as severing parts from the base material, crimping, plating or forming. For example, one 10" x 10" frame on the metal coil may contain a hundred individual metal parts that need to be separated from the roll stock and then formed. In high-volume production, automation of these secondary operations is desirable to keep manufacturing costs low. "With AccuCoil PCM, full automation of secondary operations is now possible because the precise location of each part frame is consistent," he says.

Another advantage of AccuCoil PCM is that it gives engineers new freedom to design. Because the manufacturing "tool" is a photographic image or mask, engineers are not bound by the limitations involved in creating physical stamping dies. As a consequence, front-end costs are lower, prototyping is easier, and design changes are faster and more economical. The PCM process produces intricate and close tolerance patterns in a variety of flat, metal parts with a thickness range of 0.01 to 1.6 mm (0.0005 to 0.062"). Holes or slots can be as small as 1.2 times the material thickness; and spacing between holes or cutouts can be as small as 0.9 times the material thickness.

Other design freedoms go beyond what is even possible with stamping dies. For example, says Sillmann, multiple pass PCM processes can produce true 3D machining that create areas of different thickness on the parts as well as different shapes. "This is what we mean when we say that AccuCoil PCM gives engineers the freedom to design."