Engineering Analysis Software at Offshore Technology Conference (OTC) Improves Technical and Business Aspects of Simulations for Petroleum Industry

Share:

Westminster, CA. 2 April 2008 - Noran Engineering, Inc. (NEi), a global leader in the development of finite element analysis (FEA) and engineering simulation software will be hosting a booth (#8123) to demonstrate new capabilities in its NEi Nastran software at the Society for Petroleum Engineers (SPE) Offshore Technology Conference (OTC) May 5-8 in Houston TX. NEi Nastran incorporates several new technologies that improve the real world fidelity and significantly reduce man-hours and software costs for simulations for offshore platforms, sub sea structures, underwater vessels, support ships, pipelines, mooring systems, connectors, and flexible joints. NEi invites attendees with an interest in analysis software for offshore to visit its industry webpage and sign up prior to the show at NENastran.com/OTC2008 so material may be prepared that can address their specific application.

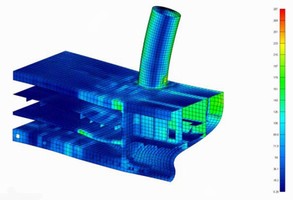

NEi Nastran determines the effects of static, dynamic, and thermal loads on structures at the design stage. New technology of interest to FE analysts in the offshore industry includes the following tools.

o Two new Automated Contact Generation tools not found in traditional FEA programs remove the tedium and significantly cut the man-hours needed for modeling contact between discontinuous members in large complex shell like structures like ships and platforms.

o Automated Surface Contact Generation (ASCG(TM)) connects different parts without need for alignment or similar meshes.

o Automated Edge Contact Generation (AECG(TM)) makes welded connections regardless of offsets and gaps between edges and faces, a common need when midsurfacing thin shell models.

o Automated Impact Analysis (AIA(TM)) performs sophisticated projectile and target collision simulations requiring only the basic starting input data. Contact and time duration between the two bodies is determined automatically and the modal frequencies and resultant accelerations calculated.

o Linear Contact Analysis is used for analyzing items with small deformation and movement like bolted connections and bearings. Linear Contact Analysis provides accurate solutions for this class of contact that are: 2 to 10 times faster, easier to use, more robust in solution convergence, and significantly less in overall cost than conventional full nonlinear solvers.

o Design Optimization finds solutions for problems with opposing parameters, for example, structures that are both strong and light.

o Full material support covers items from concrete to composites and hyperelastic rubber.

o NEi Token System allows the use of a full portfolio of simulation software for the least possible cost for multiple users in larger organizations.

o NEi Nastran 64-bit for large scale analysis handles models over 50 million degrees of freedom. Plus, there is no up charge or extra costs for usage of multiple CPUs.

o NEi Editor allows jobs to be batched for overnight and weekend runs.

About Noran Engineering, Inc. (NEi)

NEi is a world leader in engineering software for analysis, simulation, and virtual testing. The core product NEi Nastran is a powerful, industry proven, finite element analysis (FEA) solver that works with a portfolio of pre and post processors both in-house (Femap®, NEiFusion(TM), NEiWorks(TM)) and other major industry brands. Proven in industry with applications in aerospace, automotive, maritime and offshore.

Website: www.NEiNastran.com Telephone: 714.899.1220 Email: info@noraneng.com

Marketing Contact:

Dennis Sieminski, P.E.

Noran Engineering, Inc.

5555 Garden Grove Blvd.

Suite 300

Westminster, CA, 92683

Telephone: 714.899.1220 Ext. 207

Email: dennis.sieminski@noraneng.com