Electric Arc Furnace supports direct reduced iron melting.

Press Release Summary:

With electrical energy input and direct reduced iron supplied during tapping, Simetal EAF FAST DRI supports continuous melting process. Continuous supply of electrical energy during flat-bath operation avoids line harmonic distortions such as flicker, while Furnace Advanced Slag-free Tapping system enables charging, tapping, and taphole refilling under power-on conditions. Designed in combination with Siemens' Hot Transport System, furnace can be fed with hot DRI at temperatures of 600°C.

Original Press Release:

Siemens Introduces New Electric Arc Furnace for Direct Reduced Iron Melting

Simetal EAF FAST DRI Boosts Productivity of Electric Steel Production by up to 15 Percent

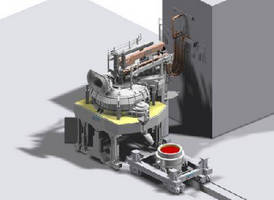

ATLANTA, -- Siemens (NYSE: SI) today announced that it has developed a new electric arc furnace (EAF) specifically developed for direct reduced iron (DRI) melting. Now available in the North American market, the Simetal EAF FAST DRI is designed for a continuous melting process as electrical energy input and DRI are supplied during tapping, which shortens tap-to-tap times and reduces specific energy consumption.

Compared with conventional arc furnaces, tap-to-tap times can be reduced by up to 15 percent, energy consumption is cut by 20 kilowatt-hours per ton and electrode consumption falls by 10 percent. The continuous supply of electrical energy during flat-bath operation not only improves productivity, but also avoids line harmonic distortions such as flicker. Using this technology from Siemens, a 150-ton furnace can increase overall productivity by approximately 15 percent.

With the patented furnace advanced slag-free tapping system (FAST), charging, tapping and taphole refilling are possible under power-on conditions. Slag-free tapping results in an enhanced alloys yield and better steel desulfurization, making installation of additional burners unnecessary.

The Simetal EAF FAST DRI is designed in combination with Siemens' Hot Transport System (HTS), enabling it to be fed with hot DRI at temperatures of around 600 degrees C. Due to the modular design of the new electric arc furnace, existing furnace installations can also be retrofitted with FAST DRI technology.

For more information about solutions for steel works, rolling mills and processing lines, please visit www.siemens.com/metals.

About Siemens

Siemens Industry Sector is the world's leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers' productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit www.usa.siemens.com/industry.

The Metals Technologies Business Unit, part of the Siemens Industry Sector, is one of the world's leading suppliers of plant construction and engineering in the iron and steel industry as well as in the flat rolling segment of the aluminum industry. The business offers a comprehensive product and service portfolio for metallurgical plants and equipment as well as integrated automation and environmental solutions covering the entire lifecycle of plants. For more information, visit www.usa.siemens.com/metals.