Eccentric Positioning Systemâ„¢ from Coventry Associates Driven by Sinumerik CNC from Siemens

Breakthrough ultra-high precision robotic machine tool positions an object anywhere in a 215 mm circle with accuracy, speed and controlled force

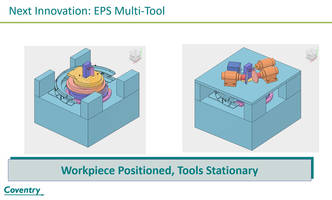

Coventry Associates (Shrewsbury, Massachusetts) has developed a three-axis system for a variety of machining operations. Called the Eccentric Positioning System™ (hereafter EPS), this fully electric system, eliminates pneumatics and hydraulics, reduces setup and cycle time, uses less energy and has a smaller footprint than any existing system of machining and is offered at a competitive cost, according to Craig Gardner, President of Coventry Associates.

EPS is a mechatronic system that consists of a stack of 3 eccentric rotary tables. By controlling the rotation of each rotary table, the precise position and angle of a tool is achieved. The positioning accuracy and adaptive performance of the EPS system is enabled by the Siemens Sinumerik CNC. Please use the following link to see an EPS explainer video, https://www.coventryassociates.com .

EPS has already been incorporated into an ID grinding machine where it has demonstrated that it can do three things that no one else in the industry can do. First, it can dress or grind any shape without the use of diamond rolls or special dressing attachments. Second, it can grind by adaptively controlling the normal grinding force rather than the feed rate which dramatically improves material removal rates. Third, it compensates in real time for deflections that result in workpiece diameter and/or taper variation, improving both quality and throughput. As Gardner states, “it has potential applications in all grinding and turning operations for the machine tool industry.” He further observes the EPS will be made suitable for any machining operation that requires a combination of high positioning accuracy and controlled force.

Coventry’s launch product, EPS SingleTool™, is designed for bearing ID grinding operations, using a single wheelhead. A shoe or chuck workhead can be used, with single point or rotary dresser for shaping any contour. Power consumption is 10kW max. and the weight is 630 kg, with exterior dimensions of 305 mm x 660 mm x 560 mm.

Coventry validated the positioning performance of the EPS SingleTool using a laser interferometer to measure its resolution, accuracy, repeatability and straightness capability. Because of the unique kinematics of the EPS, all motions are three axis interpolated moves. The results of these measurements are shown in Table 1 below. These measurements show state of the art positioning capability with a repeatability of 52 nanometers. The system also has high static and dynamic stiffness as well as the ability to grind with large forces and make rapid motions to minimize the time required to make non-grinding motions.

Coventry validated the positioning performance of the EPS SingleTool using a laser interferometer to measure its resolution, accuracy, repeatability and straightness capability. Because of the unique kinematics of the EPS, all motions are three axis interpolated moves. The results of these measurements are shown in Table 1 below. These measurements show state of the art positioning capability with a repeatability of 52 nanometers. The system also has high static and dynamic stiffness as well as the ability to grind with large forces and make rapid motions to minimize the time required to make non-grinding motions.

Coventry worked closely with the Fraunhofer USA offices in Boston, Massachusetts, plus two key partners, Saint Gobain Abrasives and Siemens Industry, Inc., to develop the initial SingleTool ID grinding application.

As Craig Gardner explains, “Our business strategy is to bring the EPS to market as a hardware and software solution, either as a complete machine to end users or as a platform for machine builders. Our solution features all-electric operation, using no pneumatics or hydraulics. We typically see resolution less than 0.12 microns with 0.05 microns repeatability, plus linear accuracy to 0.12 microns with consistent static and dynamic stiffness to a maximum grinding force of 3.34 kN. Rapid motion, including acceleration and deceleration, is tracking a 203 mm movement in 1.16 sec.”

In the next installment in the EPS series Coventry will show how their EPS Maximizer™ adaptive control will maximize productivity, quality and profitability for end users.

A series of videos demonstrating the EPS process in action are viewable at the company website, www.coventryassociates.com.

For More Information on This Development, Please Contact:

Craig Gardner, President

Coventry Associates

165 Memorial Drive, Suite C

Shrewsbury, MA 01545

Phone: 508-847-4011

Web: www.coventryassociates.com

Email: cgardner@coventryassociates.com

or

John Meyer, Marketing Communications Manager

Siemens Industry, Inc

Machine Tool Systems

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Web: http://www.usa.siemens.com/cnc

Email: cnc.marketing.us@siemens.com