Dymax GA-201 Helps Increase Production and Cuts Costs

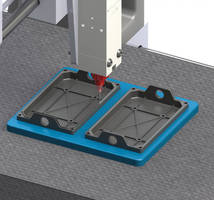

Torrington, Connecticut – Dymax Corporation is offering GA-201, a colorless, UV/Visible light-curable, tack free, moisture- and chemical-resistant FIP/CIP gasket for sealing heat sensitive substrates such as plastic enclosures. It replaces tapes, PSA die-cut gaskets, 2K epoxies, silicone rope, and RTV sealants, helping manufacturers reduce labor and part handling costs while increasing production throughput.Â

This low durometer, high elongation, silicon-free and UL 157 recognized FIP gasket acts as a barrier to prevent absorption or penetration of air, dust, noise, liquids, and gaseous substances. It is hence ideal for sealing plastic, glass, and metal enclosures, as well as plated surfaces for automotive door handles, appliance housing and critical electronic assembly, and device applications that require a soft-tack-free, flexible gasket.

GA-201 provides reliable protection, is easy to use (dispense and cure), cures without damaging heat-sensitive substrates, and accommodates design changes without investment in additional tooling. The material cures on demand, eliminating the need for racking and the waste associated with poorly fitting or improperly aligned die-cut gaskets.

Dymax Corporation develops innovative oligomer, adhesive, coating, dispensing, and light-curing systems for applications in a wide range of markets. The company’s products are perfectly matched to work seamlessly with each other, providing design engineers with tools to dramatically improve manufacturing efficiency and reduce costs. Major markets include aerospace, appliance, automotive, electronics, industrial, medical device, and metal finishing.

For additional information, visit www.dymax.com or contact Dymax Application Engineering at info@dymax.com or 860-482-1010.

Contact: Nermine Abdel-Hakim

Marketing Communications Specialist

Dymax Corporation

860-482-1010

nabdel-hakim@dymax.com