Drum Motor Drives drive food conveyors.

Press Release Summary:

Internally powered drum motors are available with USDA Dairy 304 or 316 stainless steel shell, shafts and end flanges that resist corrosion and contamination prohibited in food industry. Each motor is filled with food grade oil and hermetically sealed, making it suitable for applications requiring daily high-pressure washdown and acid or alkaline power washings. Drives have sprockets for driving food industry plastic modular segmented belting.

Original Press Release:

USDA Approved Drum Motor Drives With Sprockets, Ideal Alternative To External Drives For Food Industry Belt Conveyors

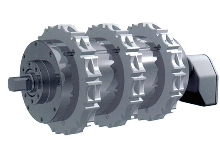

Internally powered drum motors, that feature specially designed sprockets for driving food industry modular conveyor belts, are available from Van der Graaf Inc.

Diameters from 4- to 8.5-inch can be fitted with sprockets to drive modular belting. The sprockets, mounted onto the drum motor, mate with and drive plastic modular segmented belting. Segmented belting is widely used in a variety of food applications, such as: dairy, meat, poultry and seafood processing, among others.

The sprocketed drives are custom manufactured in-house for each application and belt design. Sprockets for most patterns and designs of commercially available belting are offered, maximizing conveyor drive performance. The drum motors are available in USDA Dairy, All Stainless Steel, Stainless Steel Plated Packages featuring 304 or 316 stainless steel external components (shell, shafts and end flanges) that resist corrosion and contamination prohibited in the food industry. Each drum motor is filled with food grade oil and hermetically sealed making it ideally suited for applications requiring daily high-pressure washdown and acid or alkaline power washings.

Additional Benefits

Installation of the conveyor drive units is quick and easy requiring less than half the time needed to install conventional exposed drives. The motor's compact and low profile design eliminates all external parts, such as: motors, gearboxes, chains or belts, pillow block bearings and associated guards, increasing operator safety.

The internal AGMA 12 rated gears are made of high alloy steel with precision cut and honed teeth -- reducing noise levels to lower than OSHA requirements. Efficient and reliable, the inverter duty motors run at 96 percent efficiency, saving up to 30 percent on power consumption when compared to external drives. Maintenance needs are minimal requiring an oil change every 50,000 hours.

The drum motor product line encompasses drum diameters from 3.9 to 19.69 inches with horsepowers ranging from 0.11 to 40 hp. Standard face widths range from 9.84 to 62.99 inches depending on motor size. Standard drum speeds are fixed and range from 23 to 1369 ft/min to match an unlimited number of applications. The motors meet stringent USDA sanitation requirements and perform in extreme temperatures.