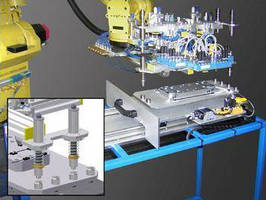

Docking Pins feature spring loaded design.

Press Release Summary:

Designed for insert molding applications, Spring-Loaded Docking Pins provide accuracy of ±.001 in. and can dock on existing mold locators. Units are sized to fit end-of-arm tools, robots, and molds. Available in custom lengths, strokes, and diameters, docking pins provide precision required in complex and low tolerance applications.

Original Press Release:

>SAS< Automation Introduces Spring-loaded Docking Pins

>SAS< Automation recently introduced Spring-loaded Docking Pins for insert molding applications (IML).

In addition to requiring precise accuracy, insert molding applications are often performing several processes at the same time. Docking pins provide the assurance required in complex and low tolerance applications.

Significant Features:

o Provides accuracy of +/- .001 inches

o Sized to fit your End-of-Arm Tool, robot and mold

o Pins can dock on existing mold locators

o Custom lengths, strokes and diameters available.

"These docking pins have enabled several >SAS< customers to consistently increase production of complex insert molded parts while reducing labor," said Robert Dalton, General Manager for SAS Automation. "Our insert mold tools and spring-loaded docking pins have automated many operations that used to be performed manually."