Disperser provides flexible micro-emulsion production.

Press Release Summary:

DISPAX REACTOR(TM) DR 2000 3-stage inline disperser provides consistent product output with flow rates from 1.5-550 gpm. Three rotor/stator combinations in series produce small droplet or particle size with very narrow distribution. Seven inlet/outlet sizes are available from 1 in./.75 in. to 8 in./6 in., with motors ranging from 2-300 hp. Tip speed remains constant at 4500 fpm. Generators include coarse, medium, fine, superfine, and 2P.

Original Press Release:

IKA®'s Dispax Reactor DR 2000

Provides Flexible Micro-Emulsion Production

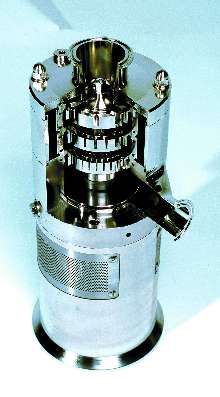

Wilmington, NC - The DR 2000 DISPAX REACTOR(TM) from IKA offers the ultimate in flexibility and scalability for the production of micro-emulsions and very fine suspensions. The unique design of this three-stage inline disperser provides consistent product output with flow rates as low as 1.5 gpm to as high as 550 gpm.

The DISPAX REACTOR is ideally suited to chemical, pharmaceutical and health and beauty products. Possible applications include the production of tooth paste, salt solutions, catalysts, shampoos, conditioners, creams, lotions, pesticides, herbicides, and fuels. Other uses include polymerization, microencapsulation, viscosity control, neutralization and PH adjustment.

Three rotor/stator combinations (generators) in a series produce a small droplet or particle size with a very narrow distribution. The DISPAX REACTOR is available in seven inlet/outlet sizes, extending from 1"/.75" to 8"/6", with motors ranging from two to 300 horsepower. Tip speed remains constant, 4500 fpm, no matter what the machine size, so results are perfectly scalable.

Thanks to IKA's proven upright modular design, generators can be easily exchanged for greater flexibility than any competitive disperser. Maintenance costs are also reduced. Available generators include coarse, medium, fine, superfine, and 2P.

All surface finishes are made for easy cleaning in sanitary environments. DISPAX units are also CIP and SIP capable, simplifying routine maintenance.

For more information contact IKA Works at 800-733-3037; Fax: 910-452-7693; visit our web site at www.ikausa.com, or E-mail IKA at process@ikausa.com.

Established in 1986 to serve the North and South American markets, IKA Works has continually grown to serve an increasing demand for mixing capabilities. IKA manufactures in-line and batch-agitator mixers, as well as mill products with unique applications in the chemical, pharmaceutical, and food industries.