Dispense Valve features drip-free cutoff.

Press Release Summary:

Pneumatically operated 752V-UHSS dispense valve has no seals or O-rings to wear out. Amount dispensed is determined by combination of fluid flow rate and valve open time. Adjustable stroke control allows flow rate to be fine tuned, while open time is regulated in increments from 0.01 to 0.001 seconds with EFD VALVEMATE(TM) controller. Applications include automated assembly machines, XYZ tables, and retrofits on existing production lines.

Pneumatically operated 752V-UHSS dispense valve has no seals or O-rings to wear out. Amount dispensed is determined by combination of fluid flow rate and valve open time. Adjustable stroke control allows flow rate to be fine tuned, while open time is regulated in increments from 0.01 to 0.001 seconds with EFD VALVEMATE(TM) controller. Applications include automated assembly machines, XYZ tables, and retrofits on existing production lines. Original Press Release:

Low Maintenance Dispense Valve Provides Accurate Filling

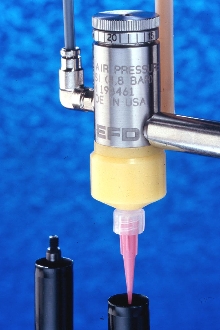

East Providence, RI USA -- The 752V-UHSS dispense valve's accurate shots and clean, drip-free cutoff increase productivity and reduce downtime in precision filling operations.

Typical applications include filling shock-absorbing devices with damping oils, loading printer cartridges with ink, and dispensing measured amounts of scents, pigments and other additives.

Unlike complex mechanical valves, the pneumatically operated 752V-UHSS dispense valve is designed for low maintenance and outstanding reliability. It has no seals or O-rings to wear out

and leak - instead, a precision diaphragm rated for tens of millions of cycles is used to ensure long, trouble-free operation.

The amount dispensed is determined by a combination of fluid flow rate and valve open time. An adjustable stroke control allows the flow rate to be fine tuned, while open time is regulated with an EFD VALVEMATE(TM) controller. Mounted near the valve, the microprocessor-based controller simplifies filling station setup and allows open time to be adjusted in increments from 0.01 to 0.001 seconds, for exceptionally consistent shots. A fast, clean cutoff as the valve closes after each cycle eliminates waste, dripping and cleanup.

Compact, lightweight, and simple to install, the 752V-UHSS is ideal for automated assembly machines, XYZ tables, and retrofits on existing production lines.