Direct Drive Motors allows large through holes.

Press Release Summary:

ULT Direct Drive motors are available in 64, 127, 165, and 190 mm O.D. with through holes up to 75% of OD. Peak torque is 1800 oz-in. Machine-wound stator coils optimize motor constant and keep axial length to minimum. Single-piece, multi-pole magnets are available with custom hubs, allowing simple integration into rotary stage design. Standard windings are available for 12, 24, and 48 V, and custom windings are available at no additional cost.

ULT Direct Drive motors are available in 64, 127, 165, and 190 mm O.D. with through holes up to 75% of OD. Peak torque is 1800 oz-in. Machine-wound stator coils optimize motor constant and keep axial length to minimum. Single-piece, multi-pole magnets are available with custom hubs, allowing simple integration into rotary stage design. Standard windings are available for 12, 24, and 48 V, and custom windings are available at no additional cost.Original Press Release:

Applimotion Expands its ULT Motor Line

Applimotion introduces new sizes of its ULT Direct Drive motor line. Peak torques up to 1800 oz-in and new designs that allow for even larger though holes. Machine wound stator coils optimize motor constant and keep axial length to a minimum. Single piece multi-pole magnets are now also available with custom hubs allowing simple integration into your rotary stage design.

New sizes include 64 mm, 127 mm, 165 mm and 190 mm outside diameter with through holes up to 75% of the outside diameter. Axial lengths are now down to an industry leading 5 mm.

More new sizes are on the way as customers choose to optimize to their low profile requirement and new low height restrictions for such things as in-tool semiconductor wafer processing. With Applimotion's rapid prototype process, initial cost for a custom solution can have a return on investment of less than 10 motors. Lead times range from four to six weeks for a custom motor.

Standard windings are available for 12, 24, and 48 volts. Custom windings are also available at no additional cost allowing speed and efficiency optimization. Applimotion has minimized cogging torque without expensive skewing of stator laminations. Torque curves have less than 1% harmonic distortion for smooth operation with sinusoidal current control amplifiers.

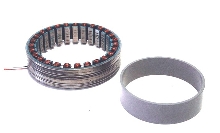

ULT frameless motors come as a two part assembly, (rotor and stator), that can be easily integrated into precision mechanical assemblies. Simple machine wound stator and single piece NdFeB rotor magnet reduces parts count and cost. For applications requiring a through hole in the rotor, the ULT motors can have up to a 120 mm diameter hole through the rotor.

Applimotion, Inc. is located in Roseville, CA. The company specializes in cost effective solutions for unique brushless motor applications. With expertise in motor design and motion engineering, Applimotion engineers create an application specific motor design for OEM customers looking for the best solution. Applimotion offers linear motors, voice coil actuators, and rotary motors with housing or frameless. Whether it's a low volume performance driven application or a high volume value driven off shore manufactured motor, Applimotion can provide a solution.